Make no bones about it,

Success is rooted in the ordinary, never in the extra.

It’s about sweating the small stuff, which in turn, looks after the big stuff.

That said, it takes wisdom to know ‘which small stuff’ to sweat.

The expert view

I recently examined the works of two of poultry’s most eminent consultative voices:

Michael Czarick and Ioannis Mavromichalis.

Thought leaders in poultry house ventilation and poultry feed formulation respectively.

Arguably, of all poultry farming input variables…

…‘¹feed’ and ‘²environmental control’ are the two most costly factors (to get wrong) and profitable (to get right).

Upon close examination, the teachings of Michael and Ioannis revealed a common fundamental that struck a chord with me.

The power of whole vs. part

Uniformity.

Meaning: The virtue of doing the right things in whole, not part.

And there are no two more important poultry production factors than:

- Delivering environmental comfort, and;

- Delivering nutritional value.

Birds who are eating (and drinking) in a well-controlled environment – simply thrive.

Said in their own words, here are Michael’s and Ioannis’ takes on the effect of producers achieving uniformity within their respective specialties.

Michael Czarick with some advice on uniformity in poultry house environmental control:

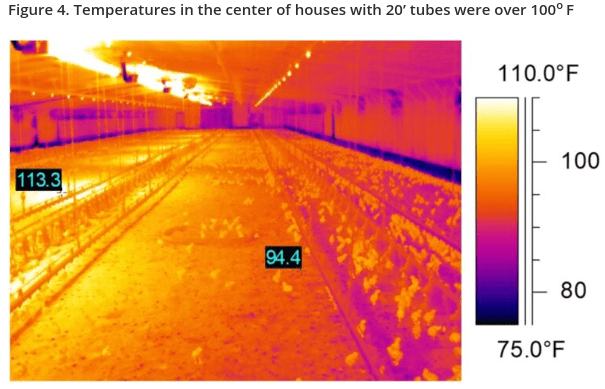

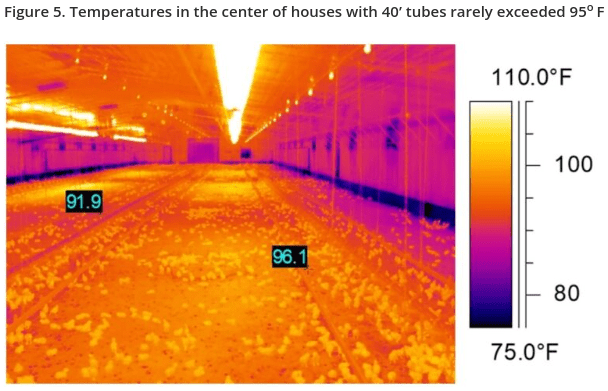

“Thermal images taken in the houses during brooding revealed that a significant portion of floor temperatures in the center of the houses with the 20′ tube heaters was over 100o F (Figures 4 and 5), whereas floor temperatures in houses with the 40′ tube heaters were far more uniform and rarely exceeded 95o F, even directly beneath the heaters.

Single central 20′ tube heater

Dual 40′ tube heaters

Though the results from the study are very preliminary, it is clear that improving radiant heat distribution can be beneficial. More uniform floor and air temperatures have resulted in improved chick distribution during brooding and slightly lower heating costs. Additional work may reveal other advantages such as dryer litter, lower ammonia levels, improved paw health and potential fuel savings.”

– feedandgrain.com

Ioannis Mavromichalis relates to the benefits of uniformity within poultry feed:

Mash vs Crumble vs Pellets…which feed presentation produces best results?

“Uniformity in pellet size distribution ensures consistent nutrient delivery. Disparities in sizes may elicit sorting behaviors, jeopardizing nutritional equilibrium.

Techniques like sieve analysis or image-based particle sizing offer meticulous assessments of size uniformity, fortifying feed quality. “

- Decreased feed wastage

- Reduced selective feeding

- Decreased ingredient segregation

- Destruction of pathogenic organisms

- Reduced dustiness and increased palatability thus

- making for greater consumption

- Reduced storage spaces

- Increased utilisation of fibrous fraction of feedstuffs

- Adaptable to bulk and mechanised feeding

- Allows partial gelatinisation of starch and modification of the protein in grains making them more susceptible to enzymatic action and better digestion.

– modernpoultry.media

Simple take-home lesson, it’s not a question of best heaters or best feed, but…

…get heat or feed INTO a bird, the bird will perform.

…get heat or feed INTO ALL your birds, all birds will perform.

Uniformity and investment

The key to successful investments of any sort is:

- trimming off the fat, and;

- doubling down on what functions.

The more uniform to goal your controllable factors, i.e. more positives than negatives, then the greater your chance of overall success.

So, success is therefore a composition.

It’s a bigger picture made up of the sum of its contributing pieces.

Each piece either ‘adding to’ or ‘taking away’ from the potential of achieving target.

Much like in competitive sports of any kind, victory is weighed in the balance of:

Scoring points, vs. Conceding points.

And the responsibility of management is to strike the right balance that, whilst accepting that no system is perfect and that conceding is natural…

- there must be a clear target,

- an understanding of strengths and weaknesses,

- plus, a firm standard of tolerance (over every factor)

…and without compromise, that the return of investments committed is always counted paramount.

In short, once standards are set – the key to good management is then to produce uniformity.

I.e. enforcing influence on the controls that drive for standard and higher still.

Diversity is unacceptable. This shows failed management.

Context

Now, let’s apply context:

Poultry farming uniformity

Producers get paid in full for birds that:

Broilers…

- reach target weight e.g. 2kg+

- meet quality standards e.g. no injury, or disease

Layers…

- lay eggs at a frequency and for a duration that is considered their peak production (300+ eggs in 70 weeks)

- lay good quality eggs i.e. size, composition

Birds that don’t meet that definition are loss-making.

Think about it…an under-weight or poorly conditioned broiler on its processing date or layer that didn’t lay enough eggs, still costs your farm direct and indirect inputs:

- feed

- water

- medicines

- heat

…etc.

So failing to recover the costs though meeting target revenue, means the bird loses you the money spent, which can never, at that late stage, be recovered.

You’ve burned money.

Whereas birds that meet or exceed target, make money.

The game in production is to get a minimum quota of your birds over the line of profitability to net an investment return.

But being realistic enough that you don’t set that bar at 100% – because as we said earlier:

“…that no system is perfect and that conceding is natural.”

That said, we need to be clear on:

- EXACTLY how many points conceded our investment ambitions can tolerate i.e. acceptable margin?

- And where we expect to concede vs. where we don’t accept conceding?

For example:

A layer farmer might accept:

- a margin of 10% accountable less-than-perfect production losses,

- but, therefore aim for 30% gross profit – resulting in a 20% return-on-investment (net).

- And they might say, within that 10% loss they expect 8% mortality and 2% under-production…

- …therefore leaving no room for breakages or poor-quality eggs.

So, to account for no breakages, they establish a zero-tolerance collection program that exalts standards of caring for the product. To uphold such standards, the owners accept they cannot cut corners on staff training or installing 1st-class storage facilities. So, they invest.

This is where strategic leadership bears dividends.

And this comes from a firm top-down philosophy that commands very particular performance standards at every turn of the production wheel.

It’s worth stressing that this realistic approach must go both ways – both in expectation of the production variables i.e. operational environment, farm staff, birds, inputs etc.

…plus, an expectation of the necessary level of investment resources required to achieve such standards.

This is the pragmatism and mutual respect amongst stakeholders that builds dynasties of success.

Likewise, on the contrary, it’s the siloing, segregation and division of not seeing eye to eye by which organisations flirt with failure.

Conclusion

So, the key to being successful in the business of poultry (as with pursuits of any kind) comes down to:

- setting the right standards, and;

- achieving target uniformity to those standards (and above).

(Not to mention, doing whatever it takes to achieve this once AND to keep doing it every time.)

Successful poultry business owners cannot afford to be partial in their view on production.

EVERY detail contributes to the end result, admittedly some more than others.

After all, you can’t blame chicks for not feeding in a cold spot (plus, it’ll be a waste of time tweaking your feed formula, when the reason chicks are underweight is poor heat distribution).

Nor, can you blame hens developing breathing issues from a dusty environment (yes, it would be wasteful to invest in respiratory medicines, rather than changing from mash to pellets, avoiding dust).

However, you CAN blame the farm manager that, knowing the root issue, neglects to correct the problem, yet expecting a turnaround.

After all, that’s why we’re here today – to learn, plan and execute better, more profitable poultry farming.

And on that note:

Do This Now…Whether a Layer or Broiler Farmer, Obtain Your Production Benchmarks from Breeder Documentation And Set Your Breakeven Standards

- Search for breeder production performance benchmarks online.

- Reverse engineer a breakeven performance level.

- Set your margin of tolerance (standard deviation).

- Template a record-keeping journal for daily performance.

- Plot daily performance against benchmark.

- Monitor performance.

Need an easy way of calculating your acceptable standard deviation?

Are You Ready To Try My Poultry Flock Uniformity Calculator?

I’ve put together a Google Sheets calculator that allows you to input your sample of bird weights and instantly presents you with an estimate of flock uniformity.

In simple terms, it tells you whether your flock’s performance is in line for being:

- profitable

- breakeven, or;

- loss-making

🎯Download This Uniformity Calculator from The Poultry Library Now (Paid)

Now over to you…

- Are you struggling with not achieving uniform performance across your flock?

- Do you have unique insight to common problems in achieving uniformity?

- Anything to add to our discussion?

Leave a comment below.

(I read every one)

Leave a Reply