This is a complete guide to broiler farming.

Any country, any breed, any model…written just for you.

So if you want to:

- start a broiler farm

- get optimal growth

- pin down your costs

- make sustainable profits

…then you will really enjoy reading this guide.

Let me show you EXACTLY how to launch a profitable broiler farm.

Contents

Broiler Farming Basics

Within this chapter, I am going to walk you through the basics of broiler farming.

(Including the business, measuring your performance and winning management practices)

I’ll show you how you can make a profitable venture with your broiler farm plans.

Understand the business

What is a broiler chicken?

Broiler chickens (Latin: Gallus gallus domesticus – translated to mean a ‘house rooster’) are farm-reared chicken kept for meat.

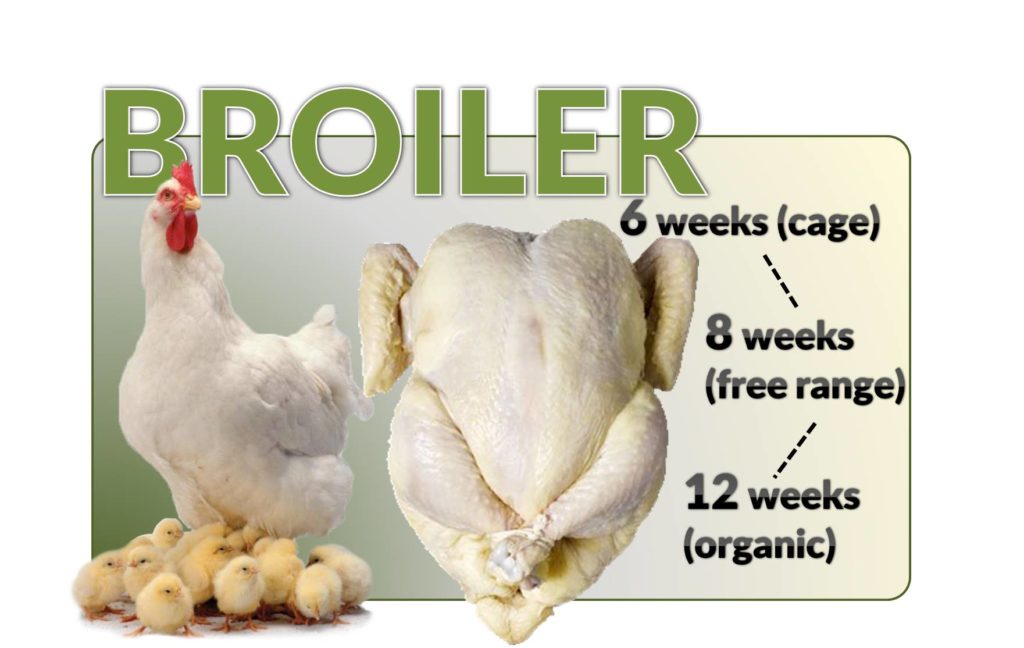

Depending on the model of farming, you would expect broilers to be slaughtered at:

- 6 weeks if raised in cages (intensive)

- 8 weeks free-range

- 12 weeks organic (pastured)

As a product, broilers are processed, marketed and sold the moment they reach an optimal size and weight.

Getting meat in front of customers as quickly as possible, at the best quality with minimal input (feed)…

This is the aim.

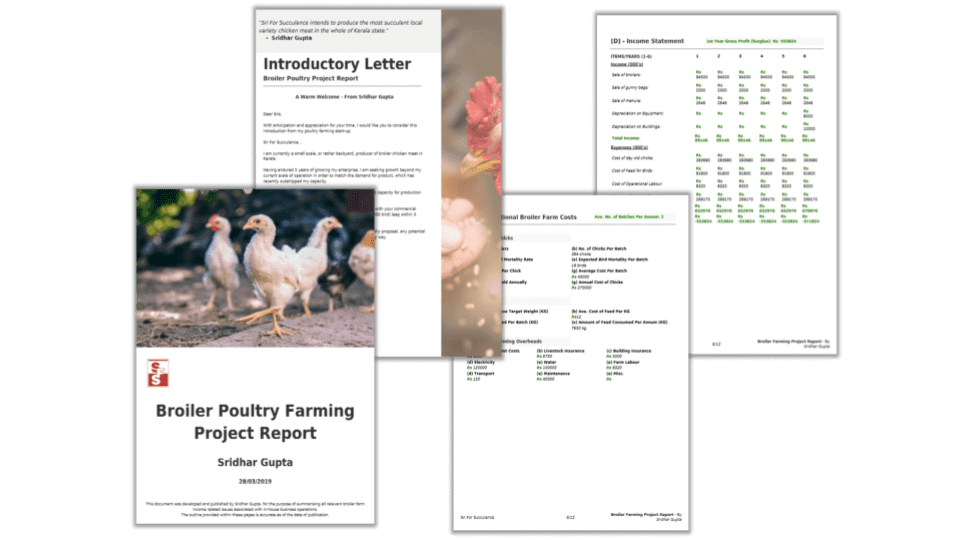

Write Your Poultry Business Plan -

in Just 90 Mins!

Poultry Project Reporter 2.0 - fastest way to write your project report online.

Get Poultry Project Reporter 2.0Choosing broiler breed

Picking the best broiler breed for your farm is really important.

Here’s why…

The broiler trade is all about physical attributes. Meat quality and quantity, as a combination, score lots of points.

The biggest headstart you can achieve – naturally – will help you get to your end goal of profit, more efficiently.

Whilst it’s not all about choosing an advantageous breed, it certainly helps.

These are traits that will give your success ratings a generous boost:

- fast growth

- quality meat

- docile/behaviour

- weight/size

- foraging ability

- taste

- weather resistance

- appetite

What do bad traits look like?

- competitive

- small

- slow growth

- poor taste

- poor quality meat

- flighty

- easily affected by weather

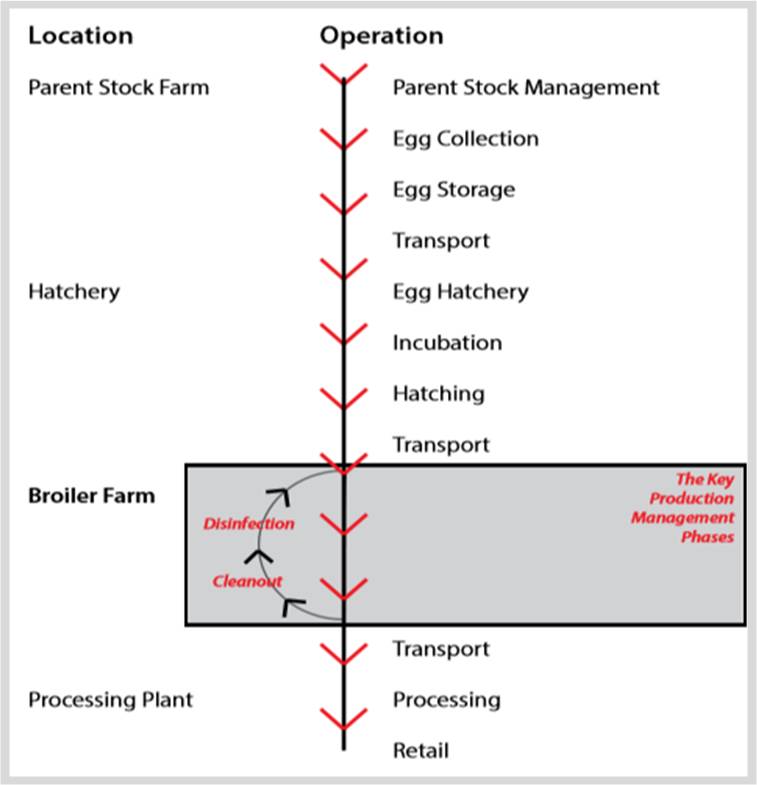

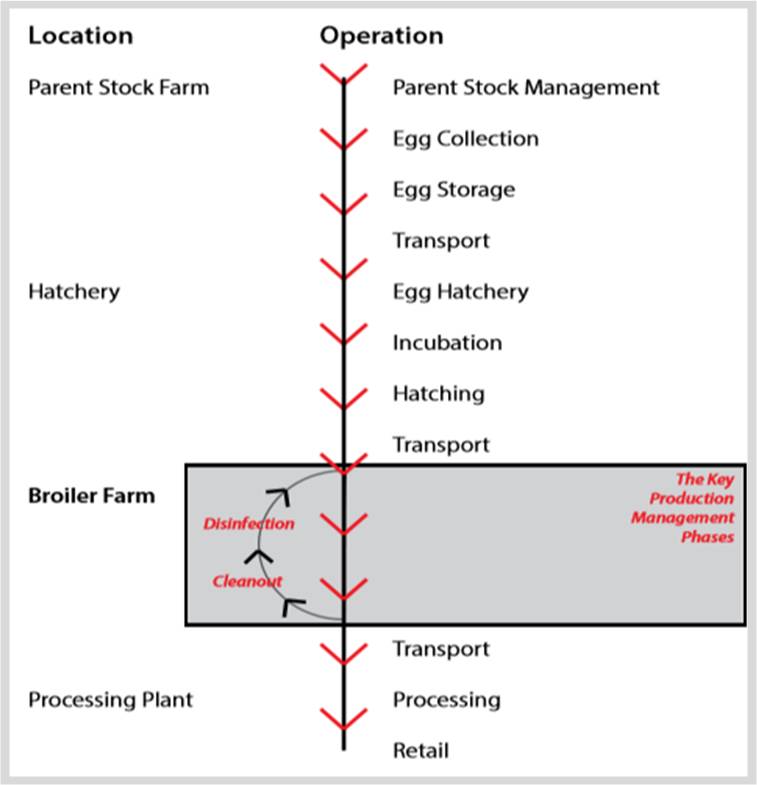

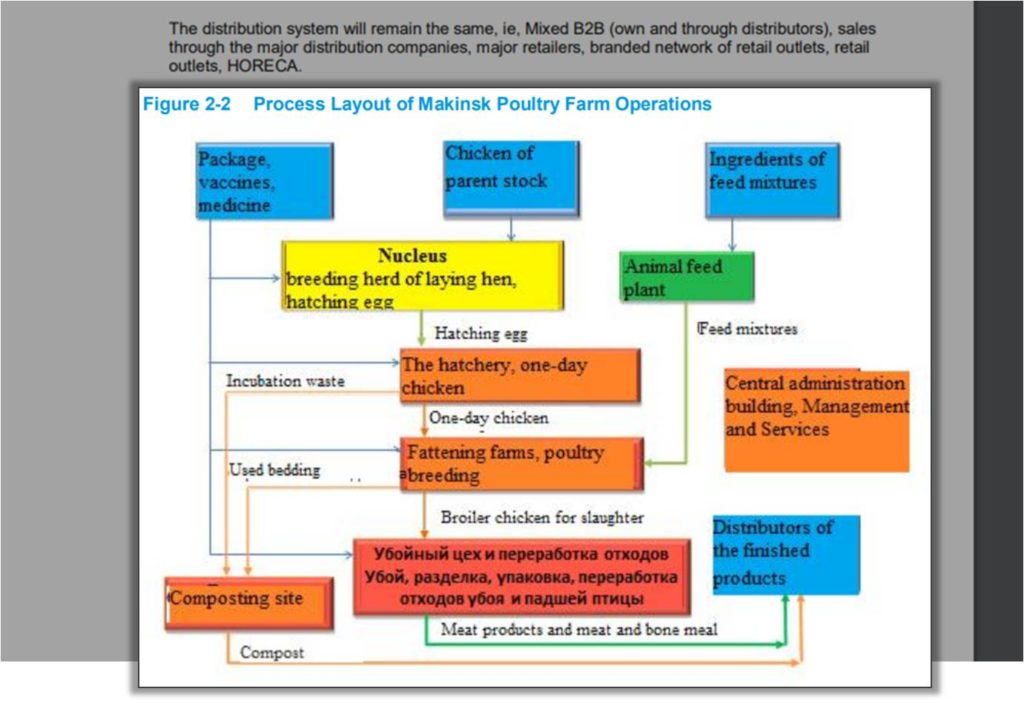

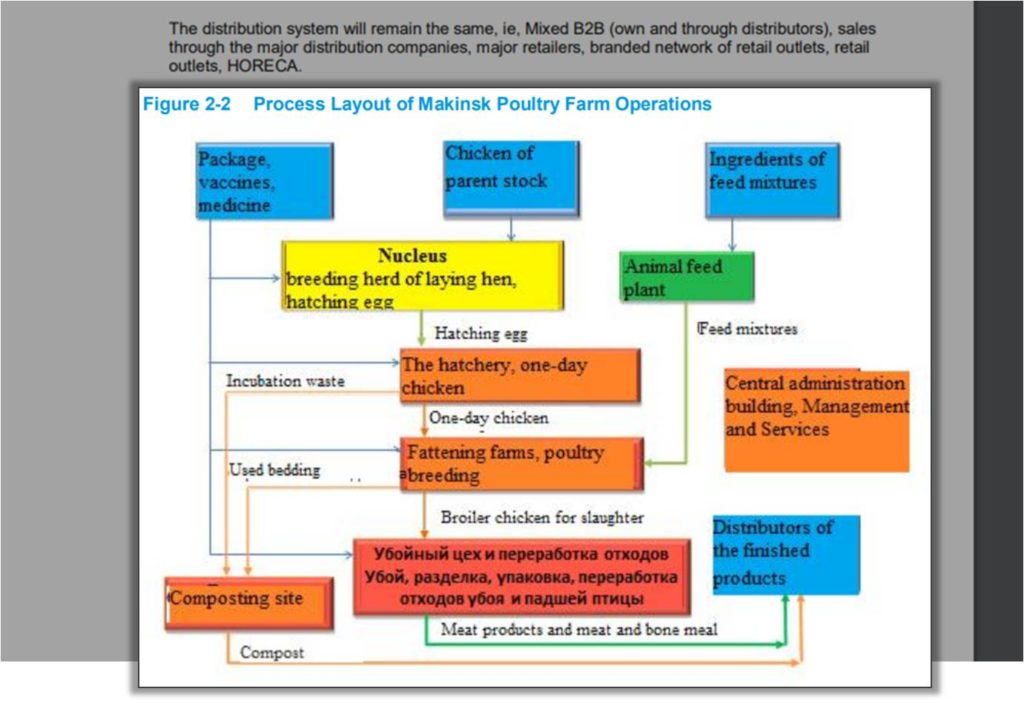

The broiler value chain – industry in a snapshot

Your broiler farm is part of a much bigger chain of events that that is estimated to feed billions worldwide with over 105.26 million metric tons of chicken meat by 2023 (Globe News Wire).

The grey box in the figure above, highlights where your broiler farm comes into play.

[This definitively answers the question: “Which came first, the chicken or the egg?…”]

Parent stock is where the journey of broiler farming begins.

They give rise to a generation of chicks which are after the likeness of the original stock.

The eggs are then collected and prepared for hatching by some specialised intermediate operations.

Once incubated and hatched,

…the chicks are then transported on the day of hatching to the farm that bought them, by batch.

Batch after batch is raised on the farm.

The farm observes very strict rules for handling safely in order to produce top-quality birds.

Quality of broiler being rated primarily by weight and size, achieved by a given number of weeks…

…6-7 weeks to be exact for cage farming (which is the industry norm for marketable, cage reared bird).

Beyond the farm, the birds are processed into carcasses and exchange hands until sold, cooked and consumed.

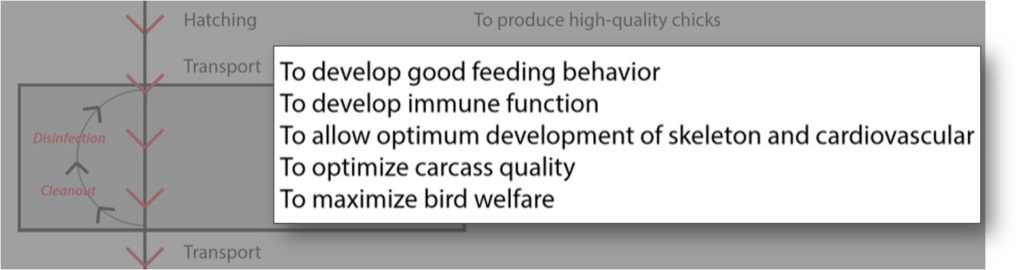

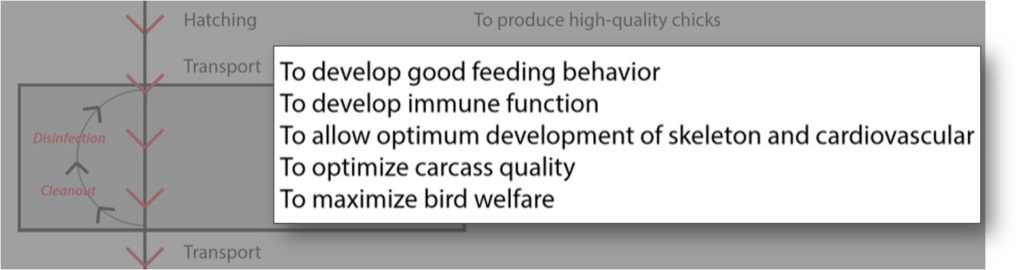

Hatchery – input

The input of your business is your baseline.

It defines where you start.

Get it wrong and you start at a disadvantage and have a much steeper climb ahead.

A good start, though, gets you in front by at least a head…perhaps neck and shoulders (wings) too if you choose well.

The key input for your broiler farm will be your batches of day-old chicks.

Cycle after cycle.

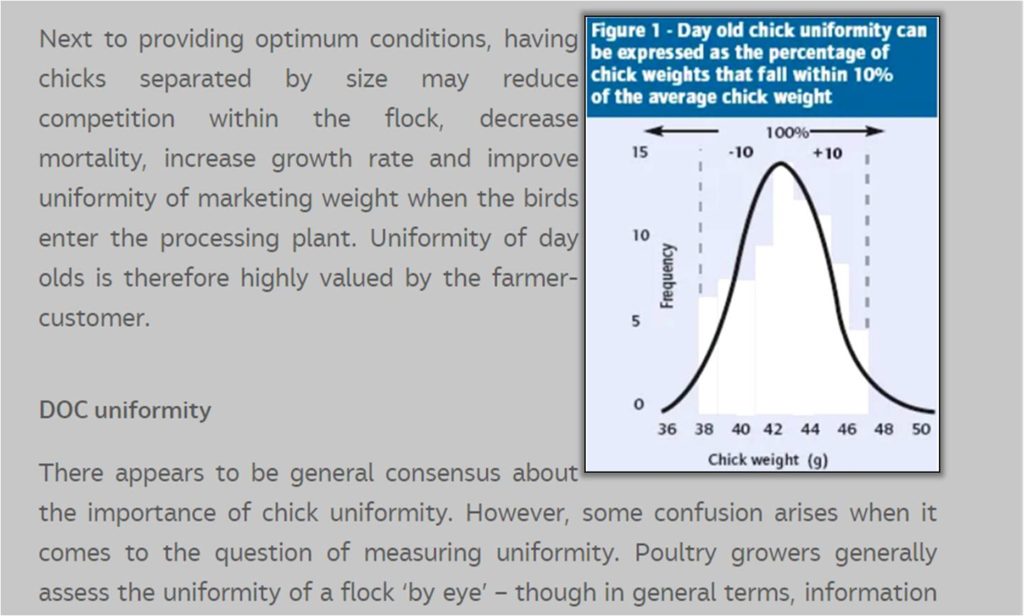

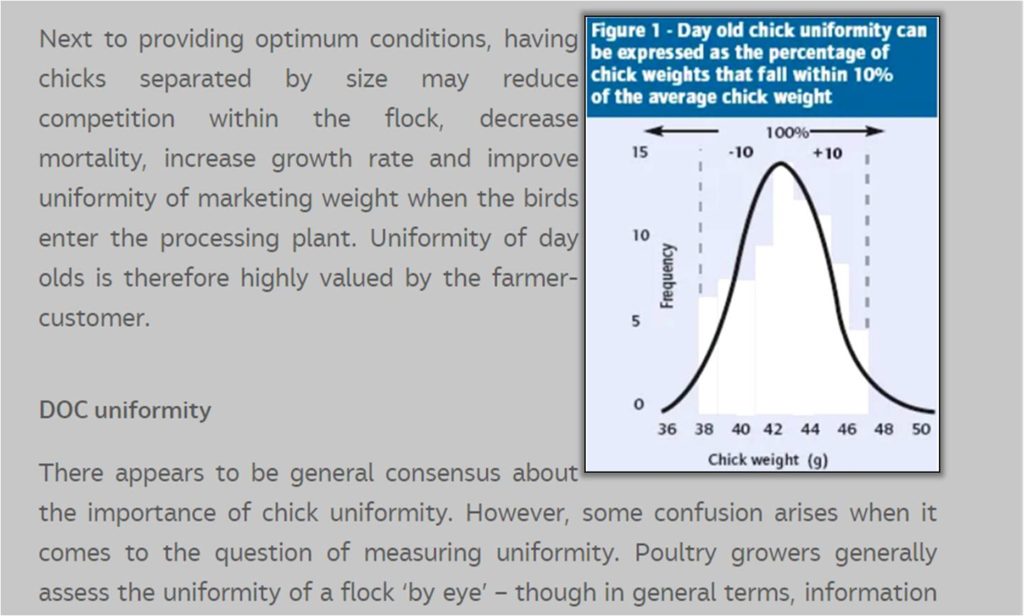

In the poultry industry flock uniformity is a useful summary of performance.

Uniformity is a percentage of birds that are within 10% of the target weight, for that age.

It’s important to remember that the overall profitability of your broiler business is influenced by every single chick (bird).

Getting birds sold depends on them meeting a marketable standard, on time.

Under-quality, birds are losses to your broiler business.

The condition that the chicks reach you in will largely dictate the quality of market-ready broiler you get at the end.

Set your batch on the right trajectory and it’s then all down to you from there.

- Feed & water them well

- Keep them disease-free

- Minimise stress

…you should be in for an acceptable output.

Broiler meat – output

Only good broiler meat that hits the quality mark gets sold.

In between investing in day-old chicks and selling carcasses typically after 6 weeks of rearing –

…there is a whole chain of events on the farm that impact quality.

This chain of events is where you add value to your industry.

Your single goal?

To produce an environment coupled with an array of processes that are delivered with such control that you can almost predict success – with every single broiler.

In a word (…or three),

ROI – Return on Investment.

Translated: Getting paid.

The more controlled and predictable your output from the broiler farm, the more you can count on your profit.

Broiler metrics & size

Broiler meat is sold on weight and accepted on overall quality.

As sales revenue is directly linked to every lb or kg of chicken mass, there are no surprises here then that the primary measure from day one is – weight.

Because of the rapid rate of growth during a broiler rearing cycle, farmers cannot afford to take their eye off the prize.

Cost

The major contributor to the overall cost of broiler rearing is feed.

Influencing the cost profile of your broiler farm will therefore largely be down to your feed efficiency.

The more feed required to produce each kg of meat, the more expensive and less profitable your product.

Less feed for the same results = more profit.

Profit

Your broiler farming profit is a collective sum of the yield contribution given by every bird.

I always see profit as a tug of war between cost and price.

Wherever the flag lands, that is where your profit (or loss) is.

The factors affecting profit (and loss) include:

- feed cost (influenced by availability, shortage, previous season yield etc.)

- broiler meat price (influenced by the general quality of meat at the market at that time)

- uniformity of flock

- flock mortality

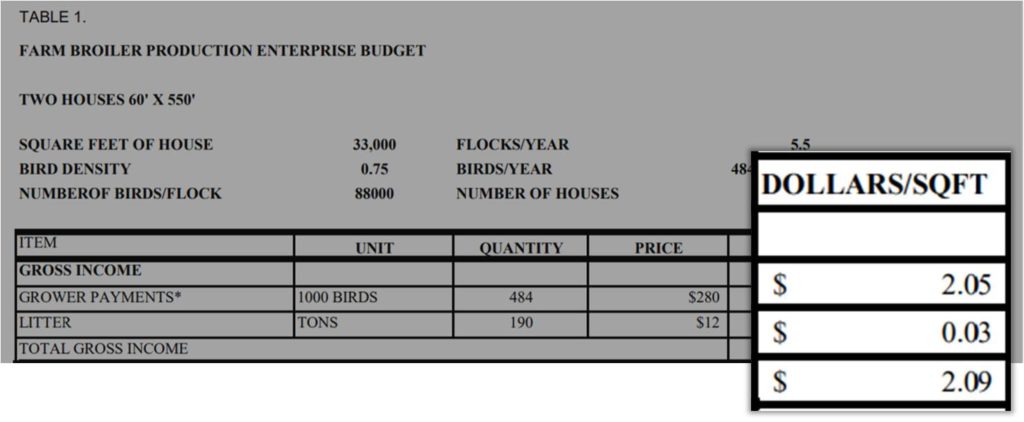

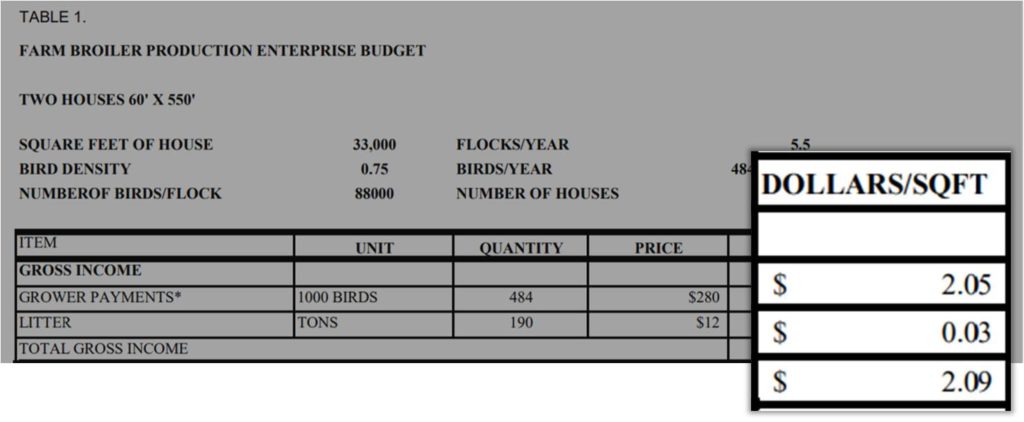

Budget

An important step in the process of running a successful broiler farm is accurate budgeting.

Being able to pin down income and costs to the cent on every dollar of money invested will give you pinpoint accuracy on projected earnings.

Get a razor-sharp budget together and carry an instant snapshot of what earnings you should expect.

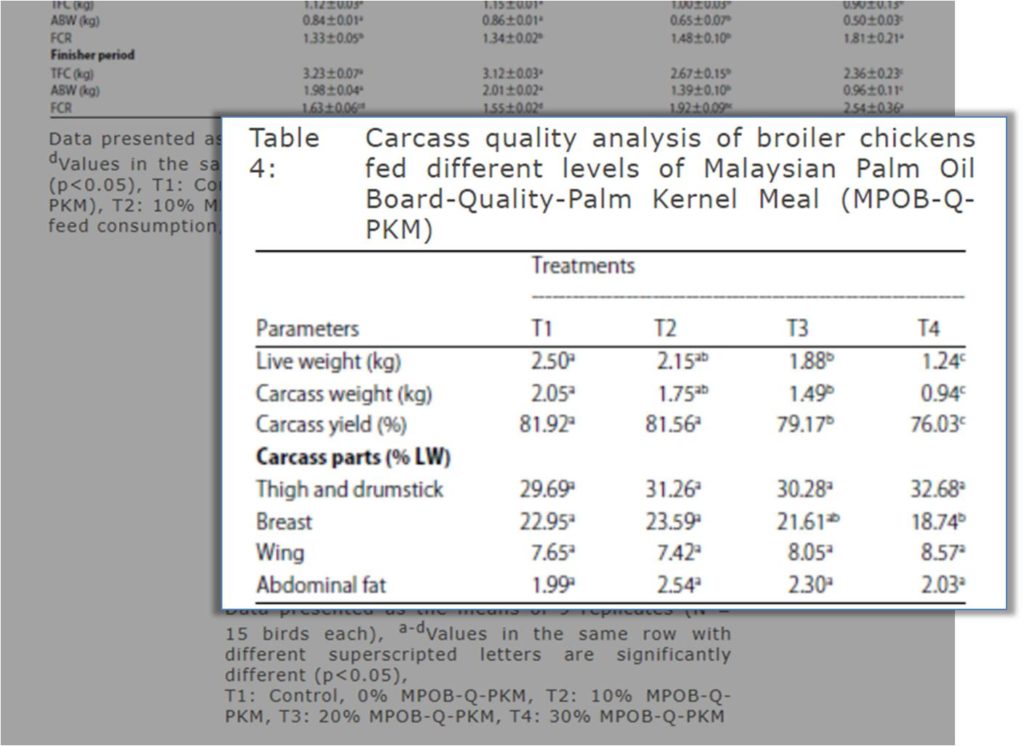

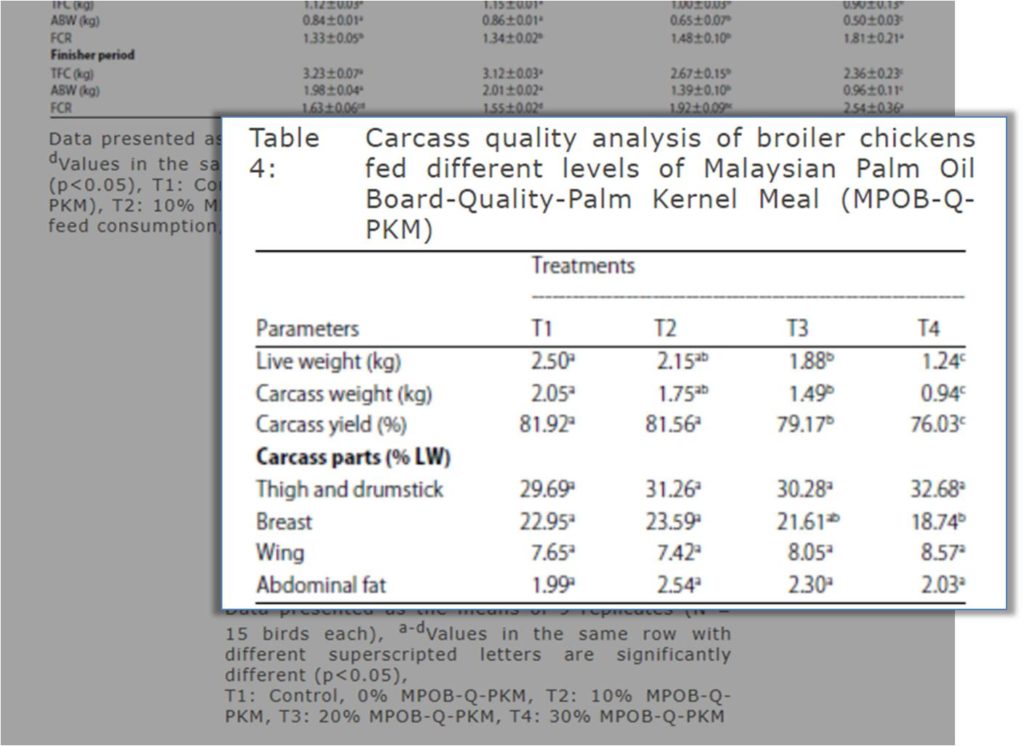

Yield

As only the meat of the bird is marketable product, an important metric for your broiler farm is yield.

This is the measure of the weight of meat as a proportion of the overall carcass weight.

In other words, yield answers the question:

“How much of the broiler carcass weight is made up of valuable chicken meat (vs. bone, fat inwards)?”

This adds a further dimension to the issue of broiler price per weight.

A breakdown of the composition of the carcass gives buyers a more accurate estimation of value.

More meat, more value.

Advantages vs. Disadvantages

The thought may have crossed your mind –

“…how does broiler farming as a business compare with layer farming for profit?”

There are many ways to measure the two related codes of poultry farming one against another.

But one of the most meaningful would have to be FCR (feed conversion ratio).

Why?

As we said before, feed cost in poultry farming contributes the majority to overall costs…

So, the more efficiently feed is converted into a product of equivalent value, the more profitable your farm.

In other words, if feeding a broiler pays more per lb or kg of meat than feeding a layer for eggs…

…or vice versa –

…whichever has a better conversion ratio, that would be the better investment on paper.

Read The Poultry Business -

Like Never Before!

Chicken Snippets Newsletter - deep poultry analysis to sharpen your acumen, by email.

Get My NewsletterCommercial performance

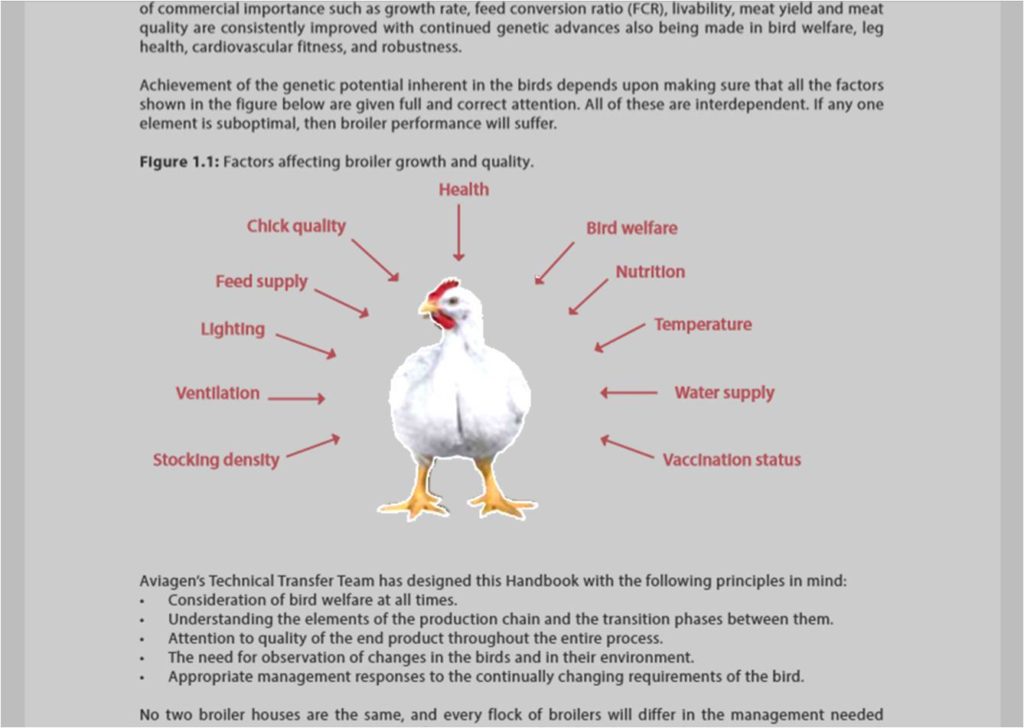

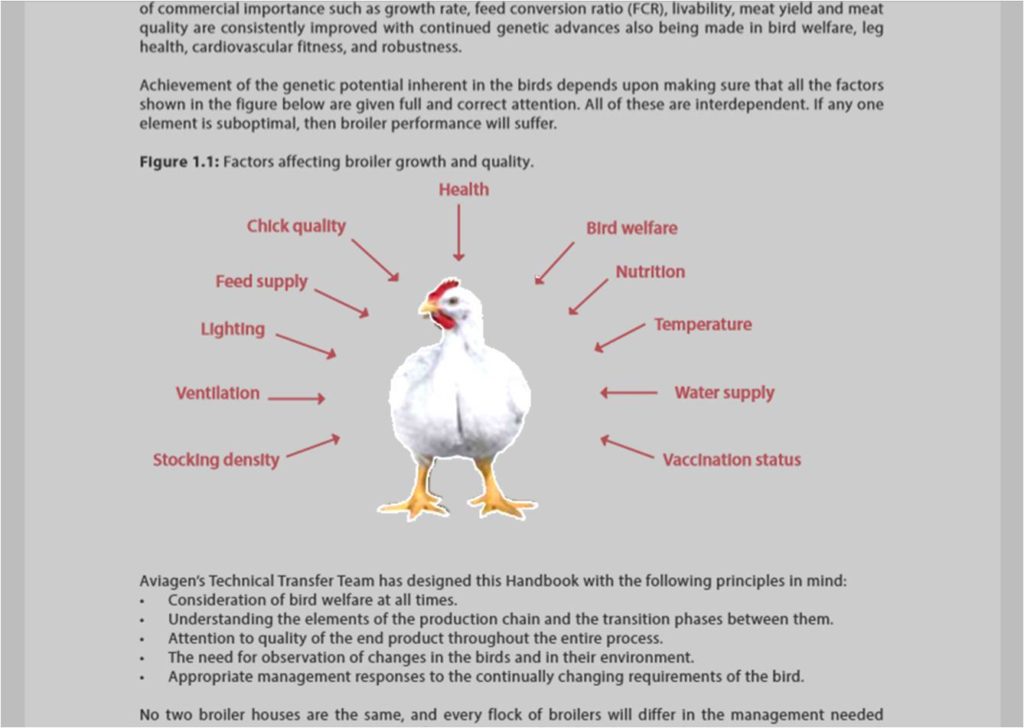

Getting the balance right

Broiler birds are highly sensitive systems.

So many internal and external factors all contribute to the end product – the amount of premium chicken meat on the bone.

These factors either add or take away from the eventual weight of a marketable broiler.

Affecting the bird’s ability to convert feed potential into valued meat…

…each factor presents an opportunity to fine-tune your farming profits.

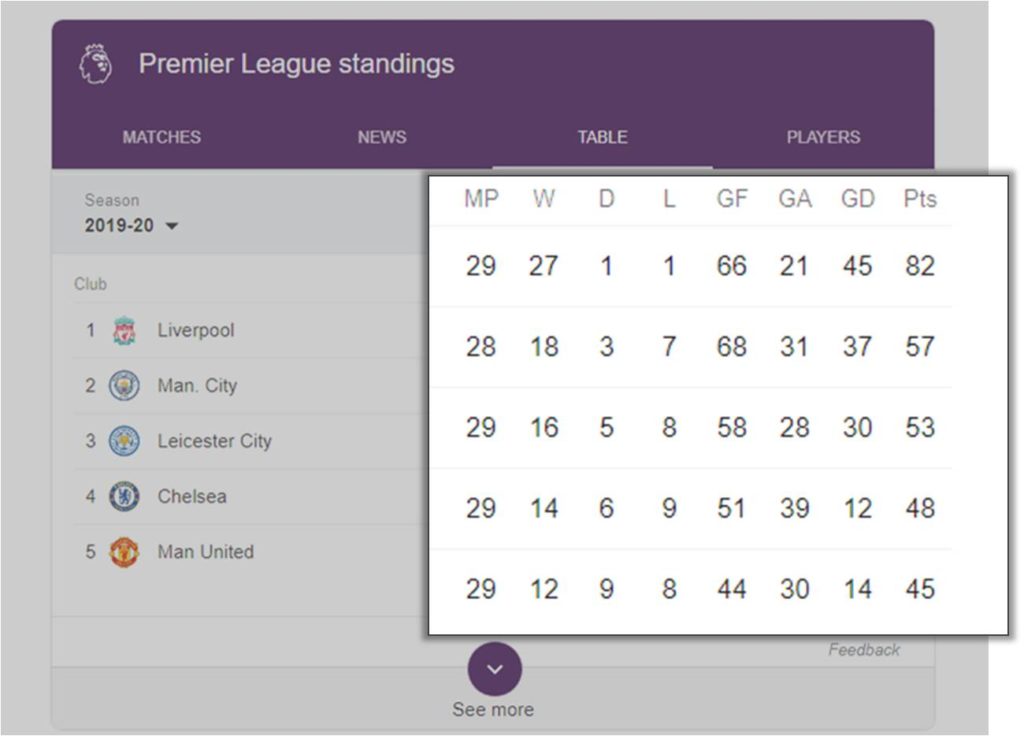

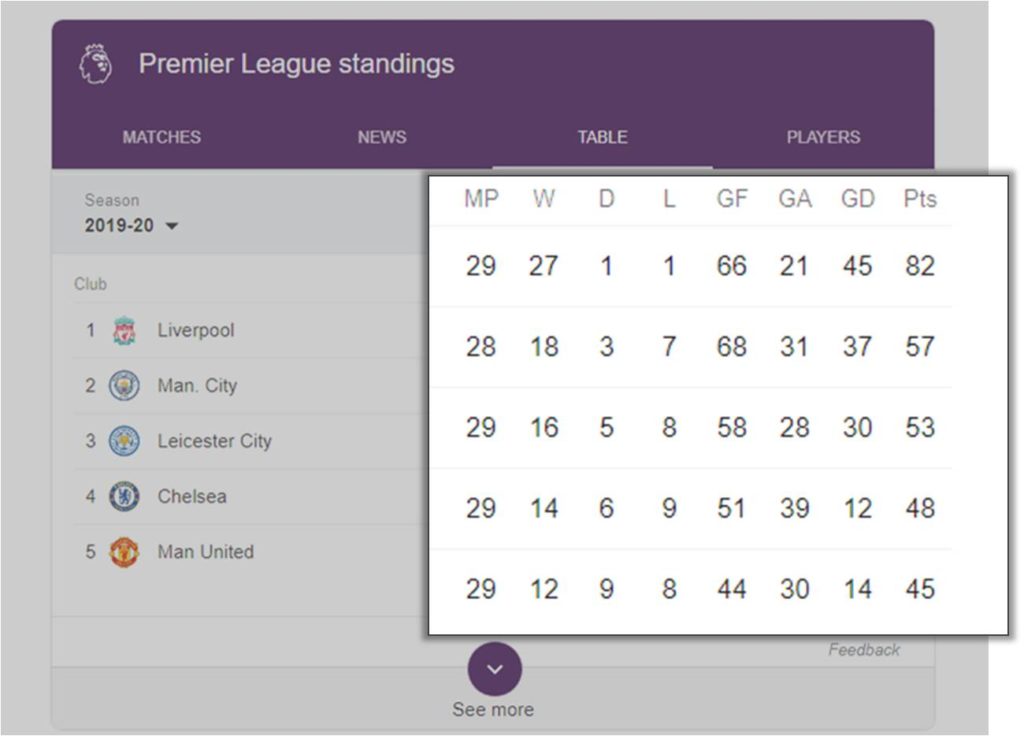

Picking up your points

The way to think about your broiler business is to think about a competitive sports league table.

Let’s say there are 20 teams.

Each team starts with 0 points, and must play one another twice – once at home and once away.

This makes 38 league matches played per team, per season (19 home matches + 19 away).

Points are awarded to teams per performance according to the result of the match.

- 3 points to for a win.

- 1 point to for a draw.

- 0 points to a loss.

The team with the most points accumulated by the end of the season is the champion.

There is a maximum potential points that a team can pick up, being 3 x 38 = 114 points (…should they win every match in a season, beating all their opponents.)

So depending on if you think along the lines of a glass half full or empty,

you could say either…

…every team starts the season with a potential 114 points and loses them along the way, should they draw or lose…

…or rather, every team starts with no points and picks them up along the way.

Each team’s ability to perform optimally depends on many internal and external factors including:

- player condition and availability

- training consistency

- weather and pitch condition

- match official decisions etc.

Broiler farming is very similar.

You start with a batch of broiler chicks at your farm on day one.

Each bird with the potential to become a marketable broiler of optimal size and weight.

Multiply the number of birds by your target weight and this is your maximum potential production for that batch.

Every internal and external factor affecting the ability to reach or fall below target.

Points picked up or points dropped.

KPIs

Tracking performance of your broiler birds is your way of keeping your finger on the pulse of profit.

Significant developments within your flock happen daily.

Age is the primary indicator. All expected developmental targets are intrinsically linked to age – often noted in days.

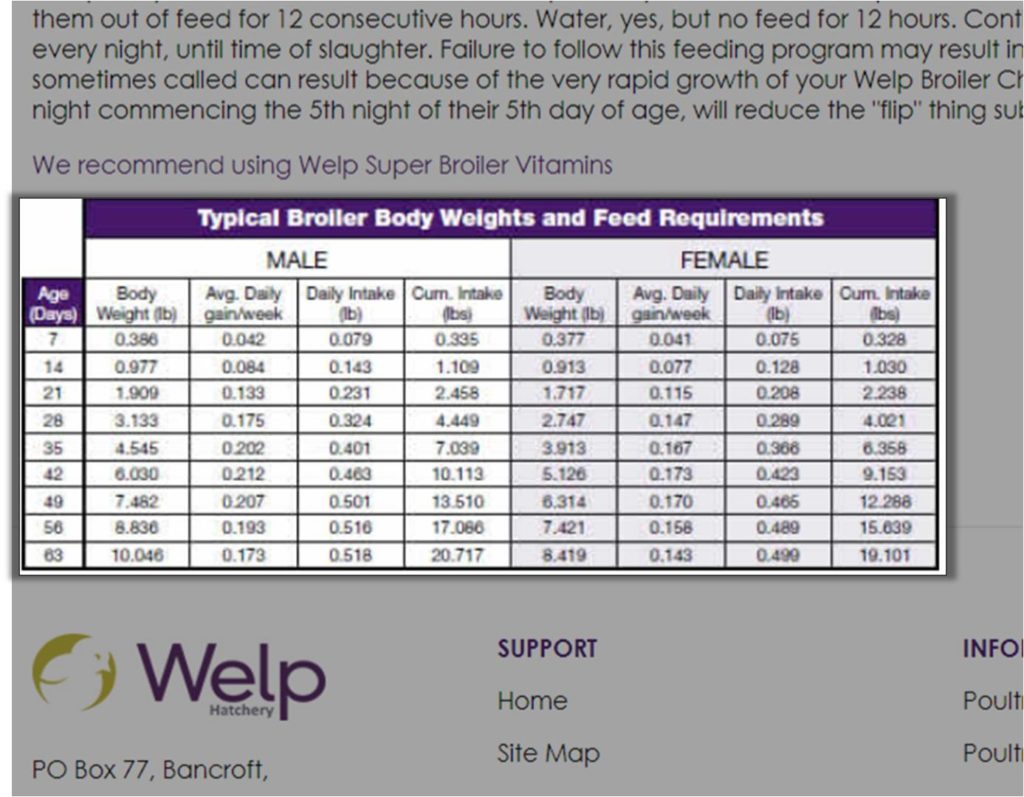

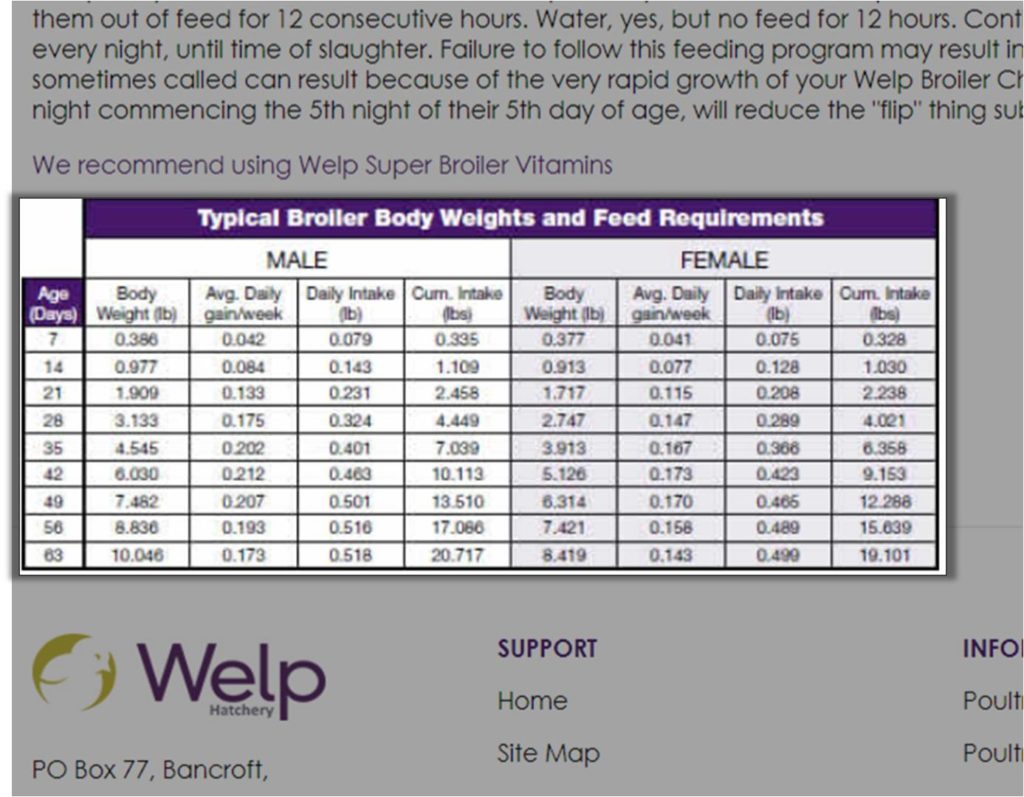

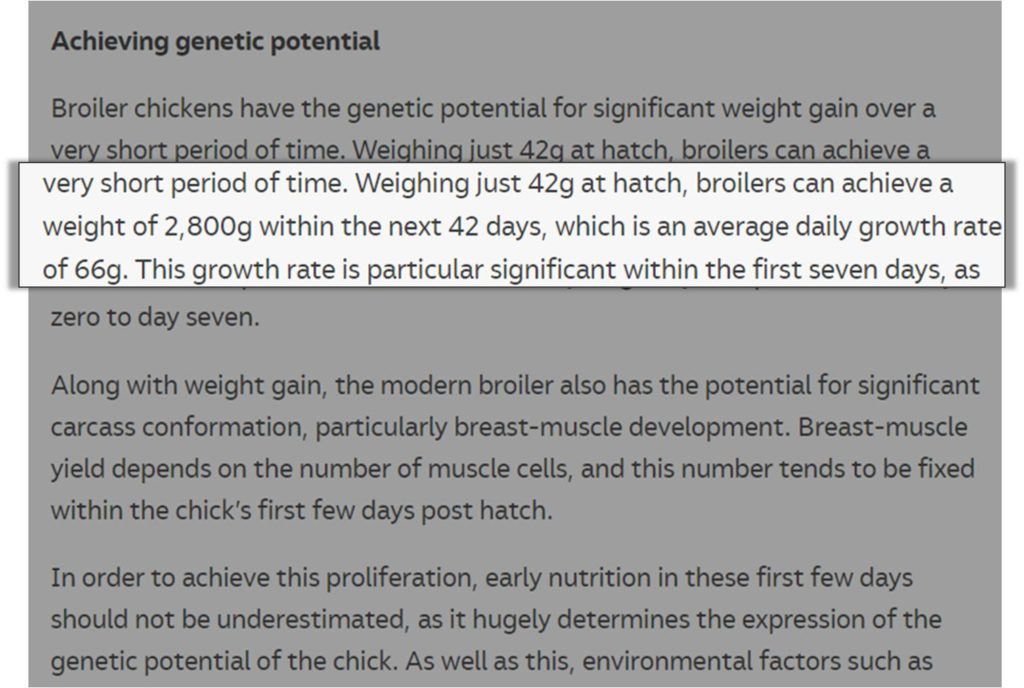

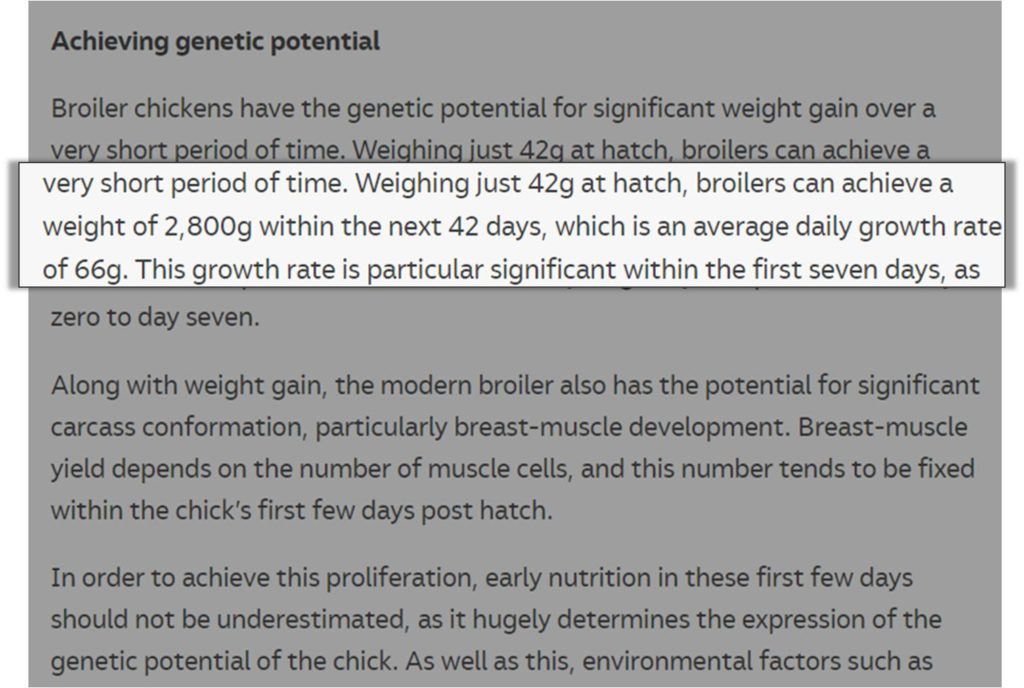

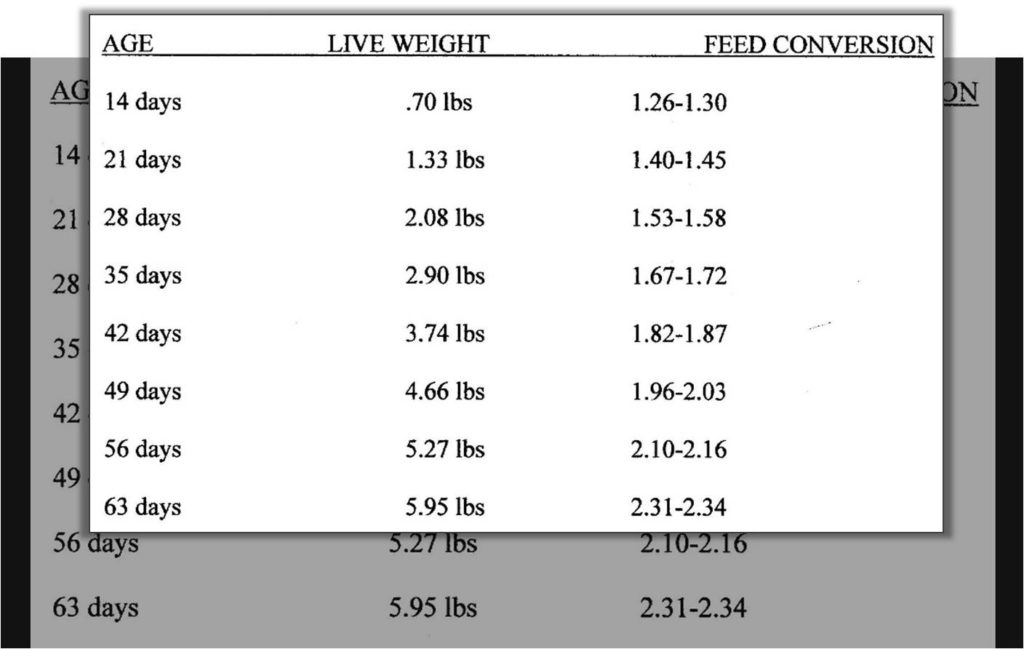

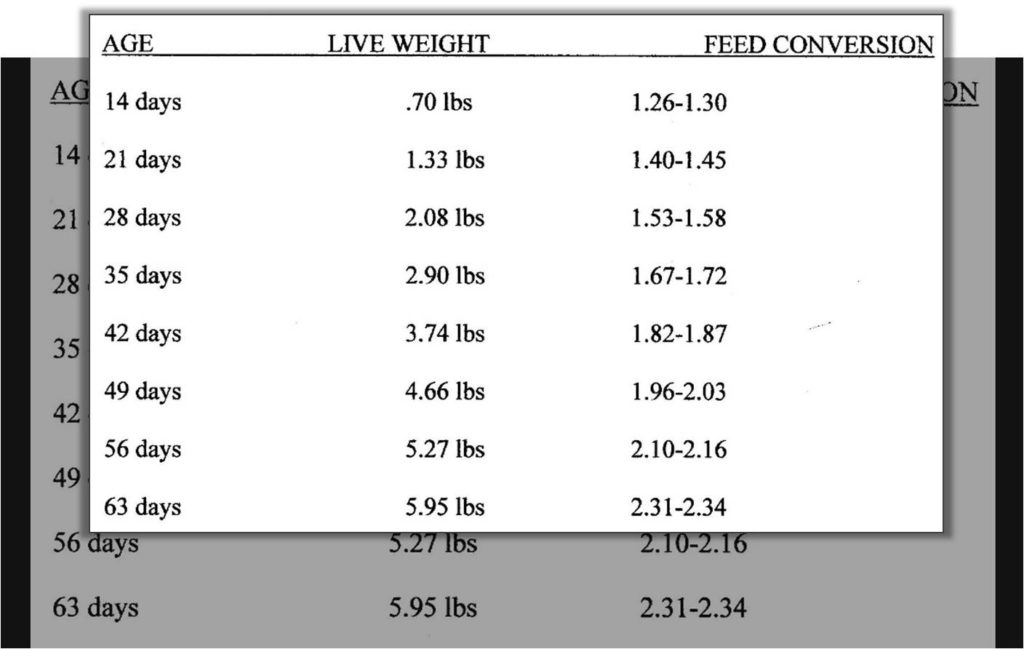

According to charts like the one above you can precisely pinpoint the target weights of your flock.

This is a growth budget. A way of tracking by major milestone whether your performance is on target, above or below.

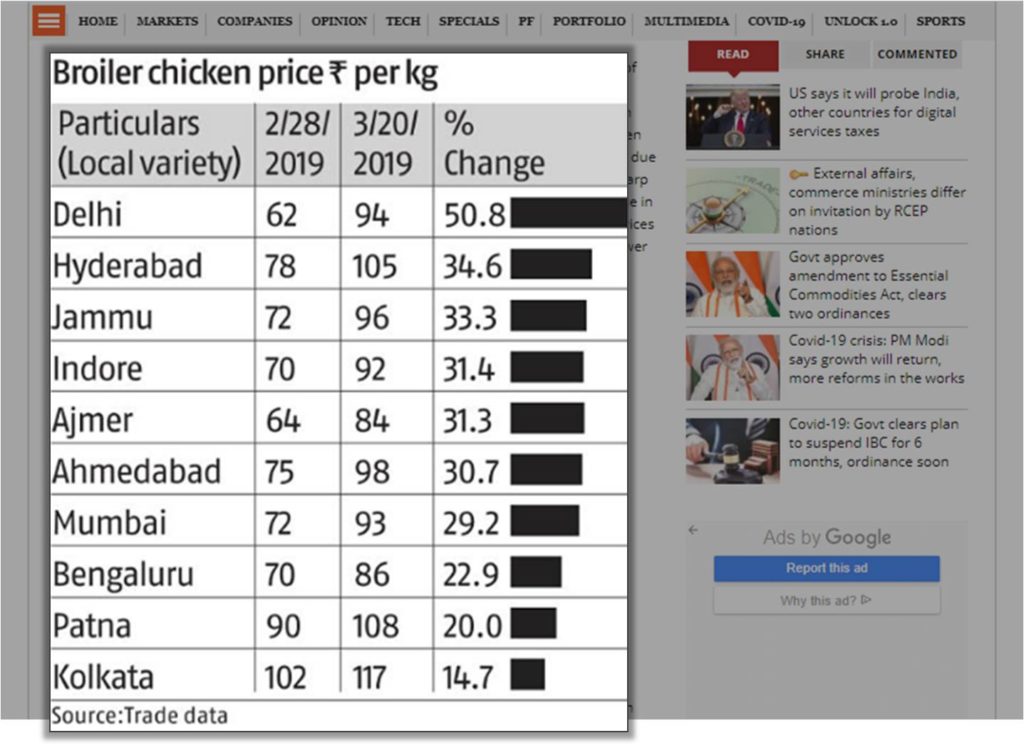

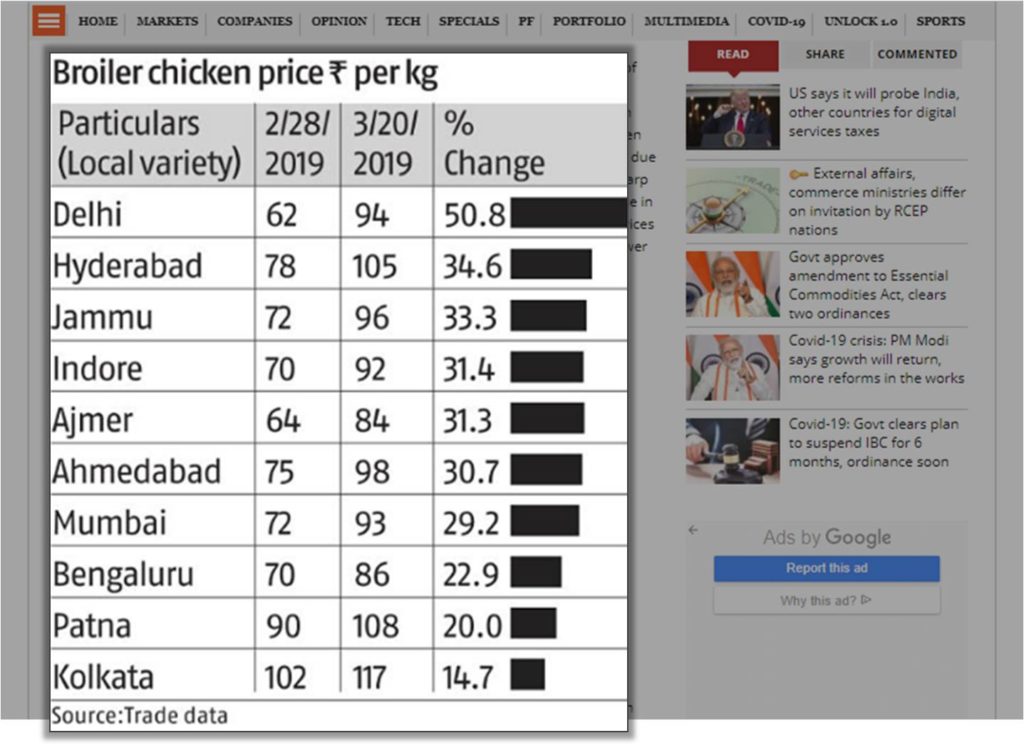

As well as internal indicators of your flock’s development, you’ll want to keep an eye on market prices.

They continually fluctuate.

Timing is everything. Your margin might be entirely wiped out by just a little contrary movement.

And whilst you are restrained by nature to when your flock hits the market (at the end of their cycle)…

…you have free licence to broker deals anytime leading up to delivery. Skill in this area can get you bottom line perks.

Market timing

Getting your broilers to market on time is critical.

If you are late, not only will you disappoint your buyers, but more importantly you will lose profit for every day lapsed.

Your deal with buyers will depend on target weight being achieved, by a given date.

However,

“…what happens if your flock is significantly underweight on the target date?”

For every day of delay in getting broilers to market, profits are eroded by feed cost to the tune of 3lbs per day, per bird.

Getting the product to the market on time is your way of avoiding disappointment.

Maintaining projected profit, protecting your earnings.

Parent stock and weight gain

The broiler business is a sprint.

Layer farming, on the contrary, is a marathon.

Broiler farming is all about reaching the finish line of target weight, in record timing – and with good quality.

Over the decades of industrialised broiler production…

…the market has devised more and more methods of breaking world records.

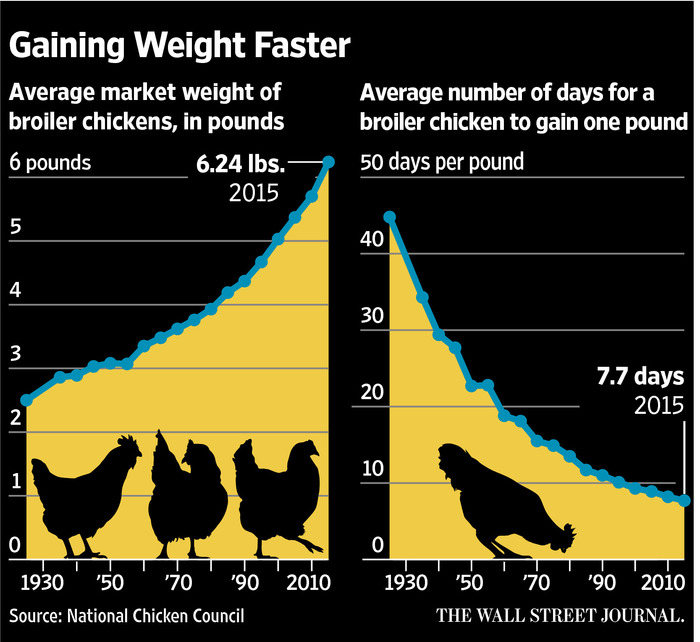

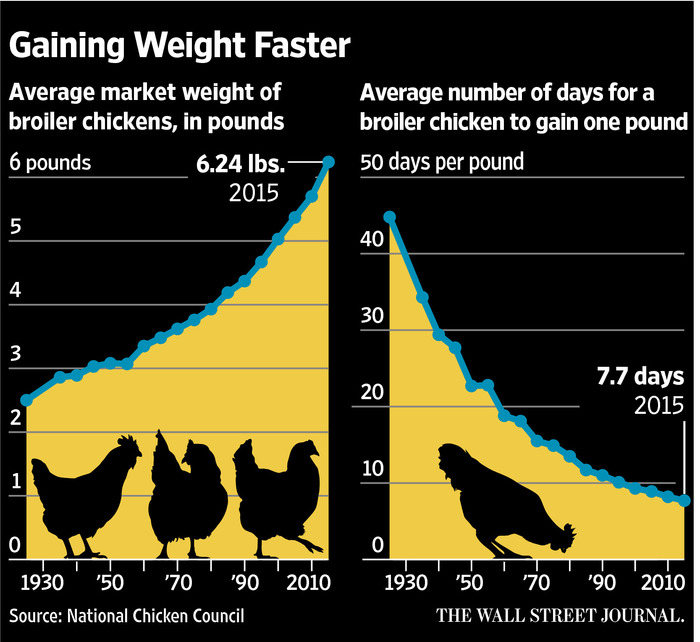

Over the last 80 years according to the graph above…

…the average number of days for a broiler chicken to gain 1 lb has dropped from over 40 days to only 7.7 days.

Master The Poultry Business -

Like a Pro!

Poultry Courses Online - most actionable and interactive online poultry course.

Join Poultry Courses OnlineHow was this achieved?

Largely by selective breeding of parent stock.

Choosing the stock with the quickest growth traits and inbreeding them until the timing is shaved down.

Model

With broiler farming, there is a trade-off between quality and quantity – like with any business.

Know where you stand. Set your stall out according to the values of your customers –

And serve them.

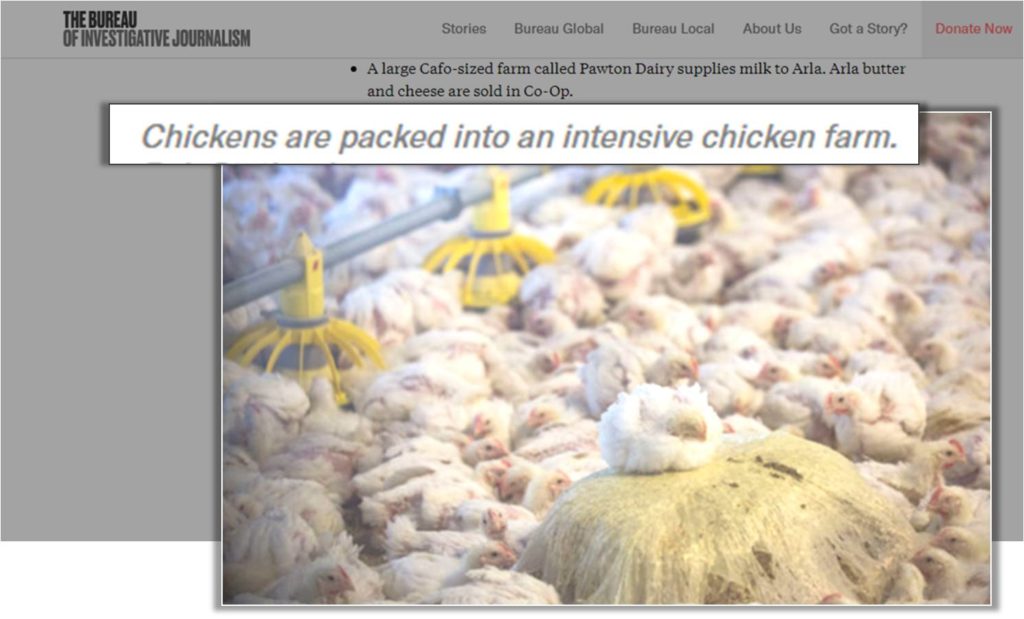

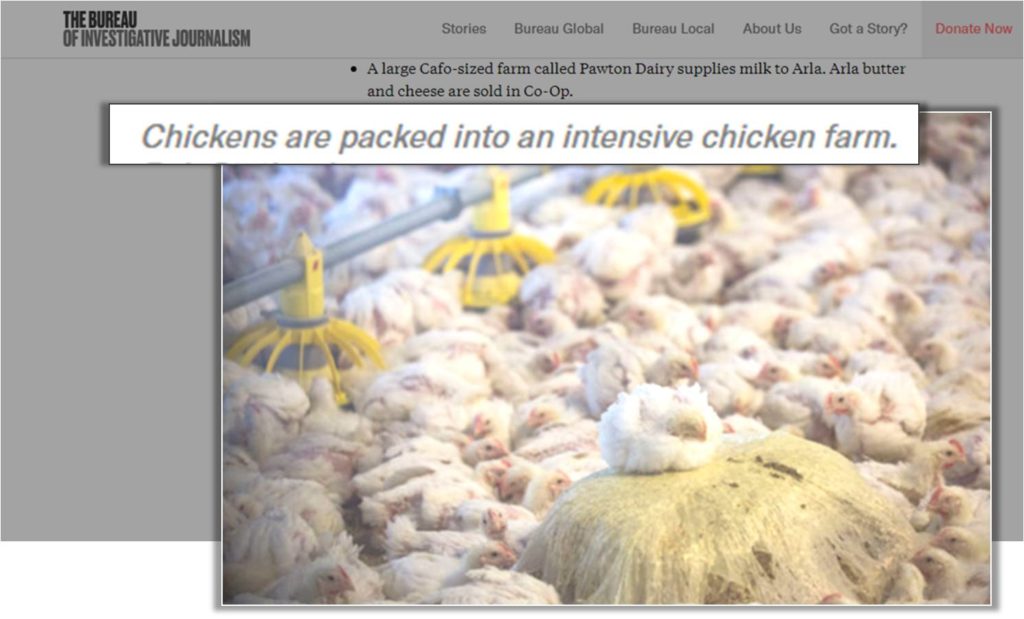

Cage (intensive)

The cage broiler set-up is built for large scale and quick results.

Birds are stacked and piled high for optimal density and volume combined.

Capital investment is spent on equipment and environmental control systems.

Free-range (organic)

Organic or pastured broiler rearing is non-intensive.

A more liberal rearing experience for the birds (e.g. grazing on pasture), giving rise to richer nutritional content.

Take this chicken caravan, pulled by tractor:

…a great solution for allowing your flock the freedom to roam, yet controlling their containment.

Birds are given a more liberal rearing routine with the end quality of meat in mind, more than sheer scale.

The end meat-product appeals to a more discerning buyer who is willing to pay more for the benefit.

Essentially, a premium product.

Management

The secret to broiler farming success is meticulous management.

Farm success is built largely upon operational procedures and processes.

The handling of each individual variable directly impacts your bottom line.

The more consistent your handling, the more reliable your future profits.

All in all out

The golden rule with broiler farming management is “all-in-all-out”.

What does this mean?

AIAO (all-in-all-out) is when a broiler farm manager accepts only one batch of broiler birds to rear at any one time on-site.

In such a rearing system you will NEVER have more than one batch of birds occupy the farm at any one time.

Why?

Take a look at this expert viewpoint from Dr Ahmed Atef, Poultry Nutrition Specialist (at The Centre for Concentrates & Feed in Cairo, Egypt):

In our post on “Broiler Rearing System“, Ahmed Atef a participating poultry expert in The Big Book Project member’s program says,

“All in All out system is the best rearing system in one farm…eventually lead to a successful cycle.” – Ahmed Atef

According to Ahmed, cohabiting flocks on your farm will increase cross-infection from viral or bacterial pathogens.

Managing one flock at a time per farm means that each farm naturally faces a 6 week – or above (full cycle) lag in between flocks. This also slows down cash flow.

However, the set-up is less vulnerable to the outbreak of disease and your profits are potentially safer.

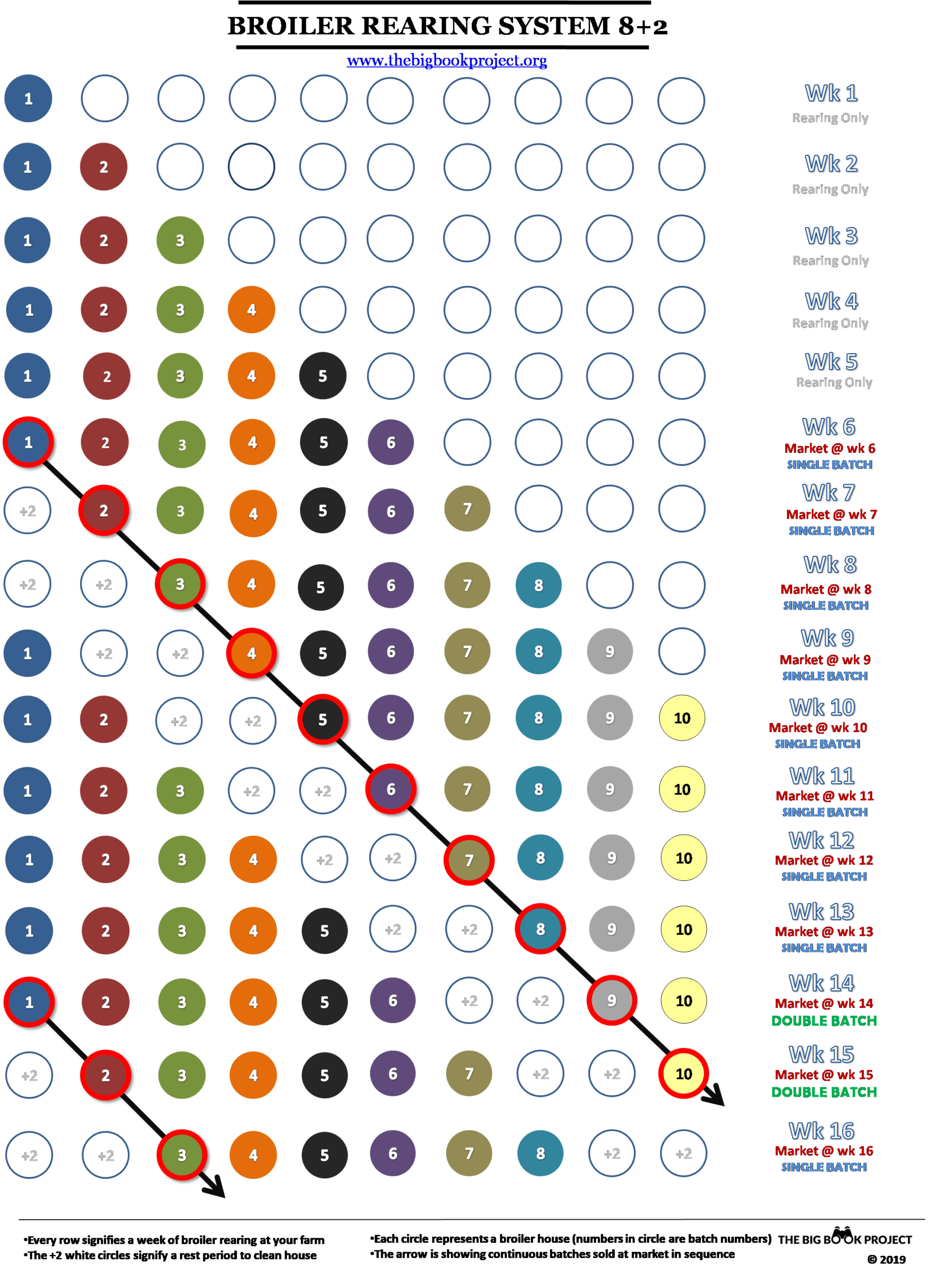

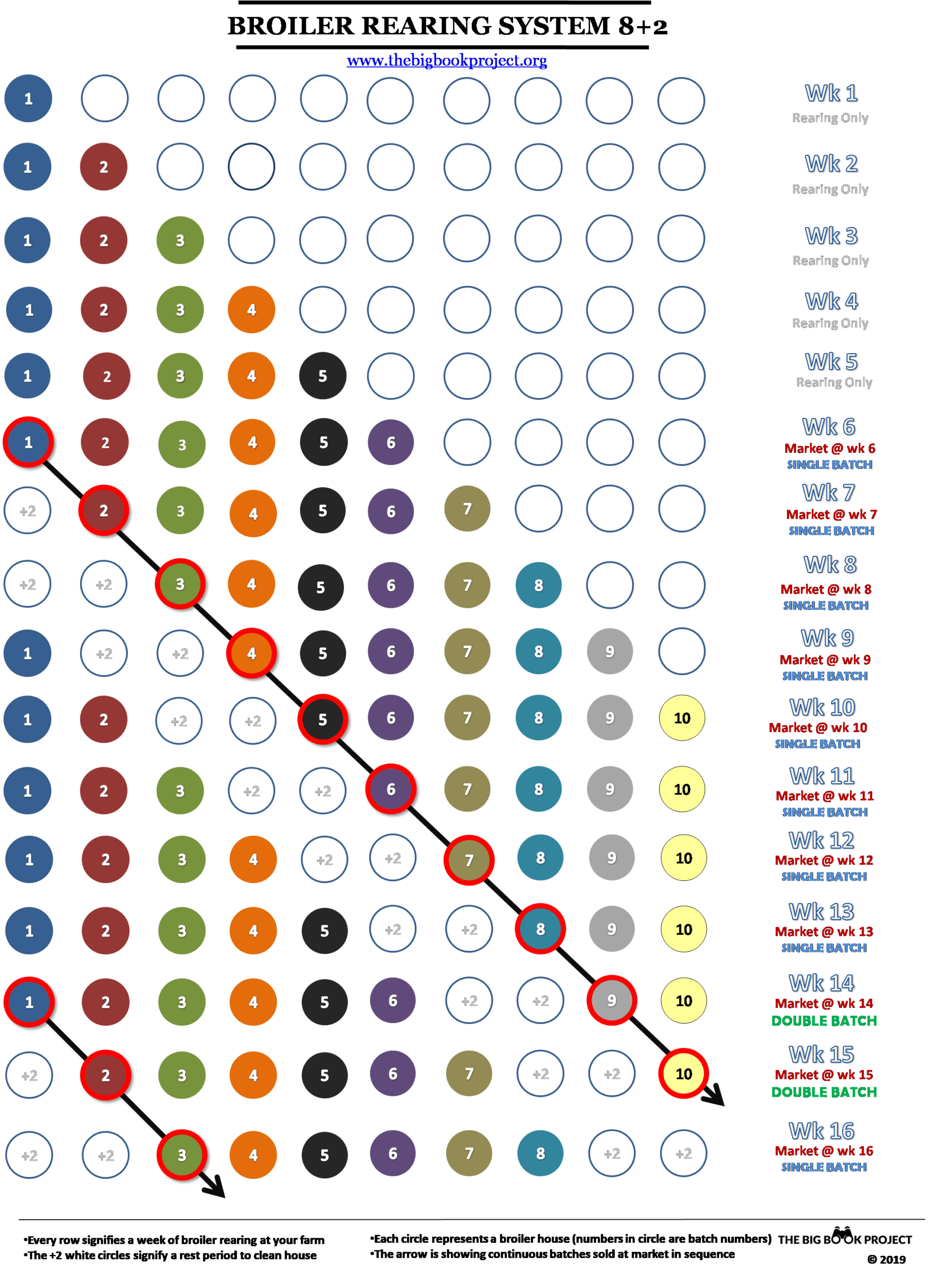

If you want to achieve a more frequent arrival to market, like in this example of 8+2 broiler rearing (but still maintain All-in-All-Out)…

..the answer (although a costly one) is to set-up other broiler farms to operate simultaneously.

This way you could arrive at the market more frequently than a full cycle’s interval of any one batch.

Even delivering broiler meat to market every week, if you liked.

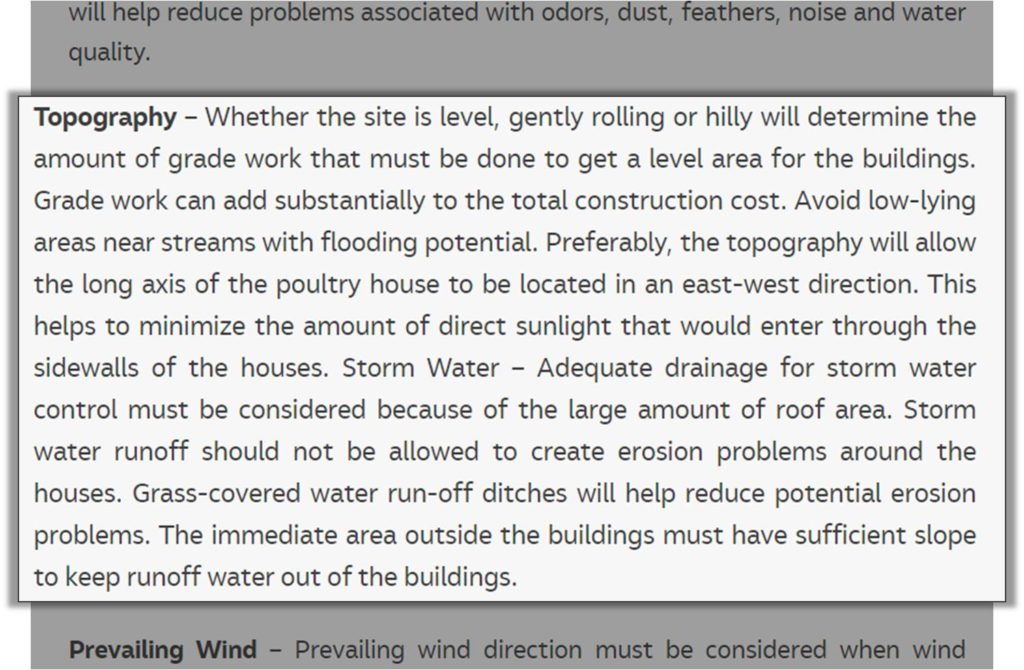

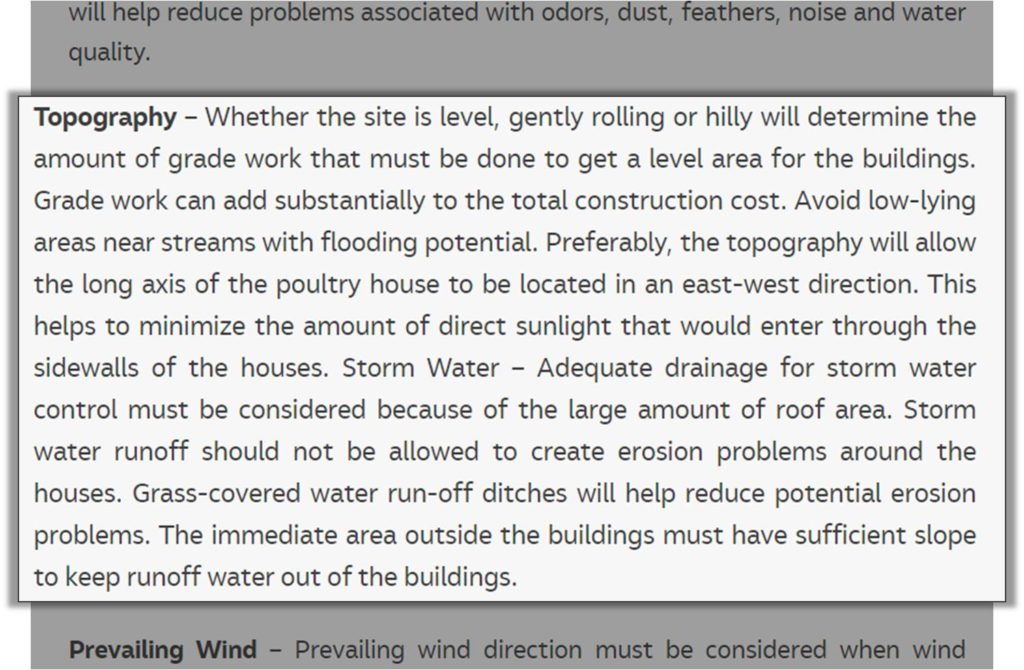

Location & orientation

Make the most of your natural surrounding on-site the broiler farm and you can save cost and improve yield.

Carefully considered positioning of your site can make all the difference to future business success.

Poultry house conditions such as ventilation and temperature can also be supported by where you site your farm.

Also, water availability is critical.

Advance Your Poultry Project -

Into Maximum Profits!

Advanced Poultry Pickup - hands-on, 1-to-1 poultry business consultancy - anywhere.

Start Advanced Poultry PickupThe further your farm is away from a clean water source, the greater your cost of transport.

Size

The scale or size of your broiler farm comes with its own challenges.

The larger, the more:

- capital investment for…

- land, buildings & equipment

- payroll

- expenses

But with larger inputs, come potentially larger outputs and cost advantages.

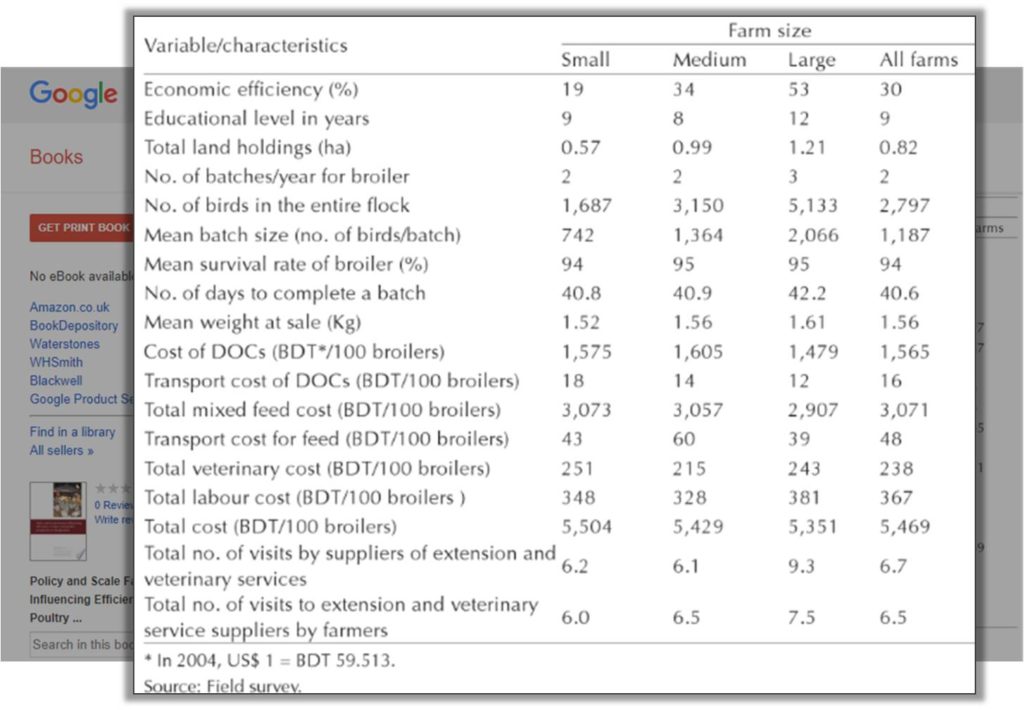

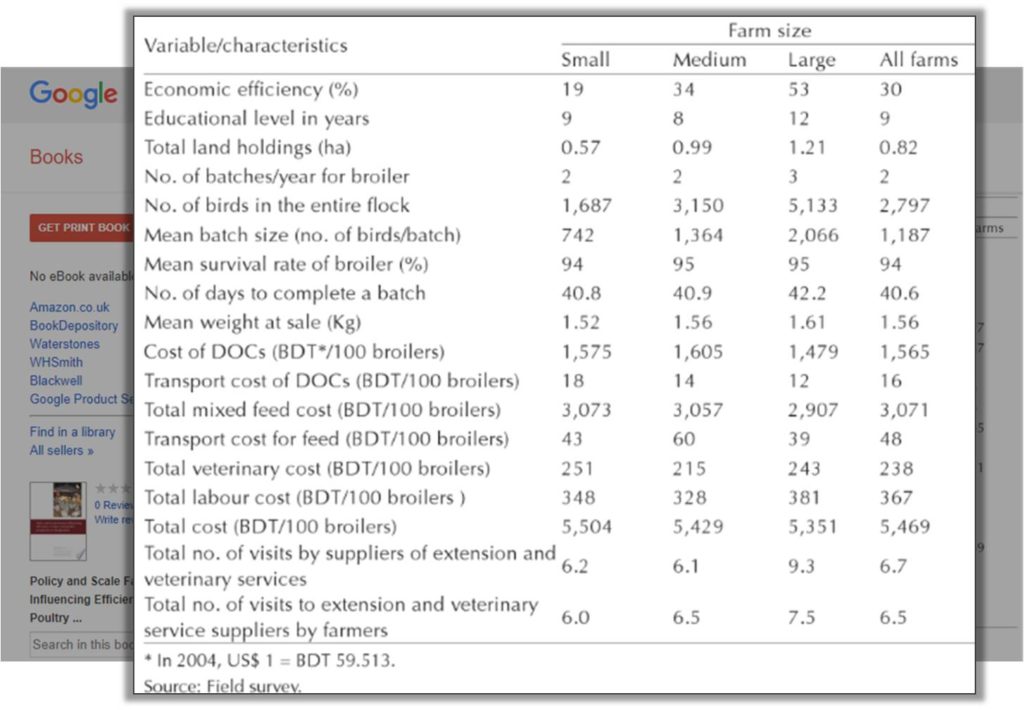

The table above was a comparison field survey carried out in 2004.

It compares the size of broiler farms and their economic profiles.

What was the bottom line?

Larger farms (farms with more broilers per batch) required more:

- training

- landholdings

- visits by extension and vet services

..but because of greater financial efficiency from:

- cheaper cost per day old chick

- cheaper cost for transport from the hatchery

…the net profit margins of larger farms exceeded the profit of smaller farms.

However,

this is not always the case in business.

And scale is an individual choice.

There is such a thing as biting off more than you can chew.

Site planning & layout

Operational success and efficiency have a lot to do with proximity.

If things which you need are nearer to your hand, they are more readily available for use.

This means you work harder, quicker and finish sooner.

Also, you have fewer accidents, spillage (waste) and clock up less error.

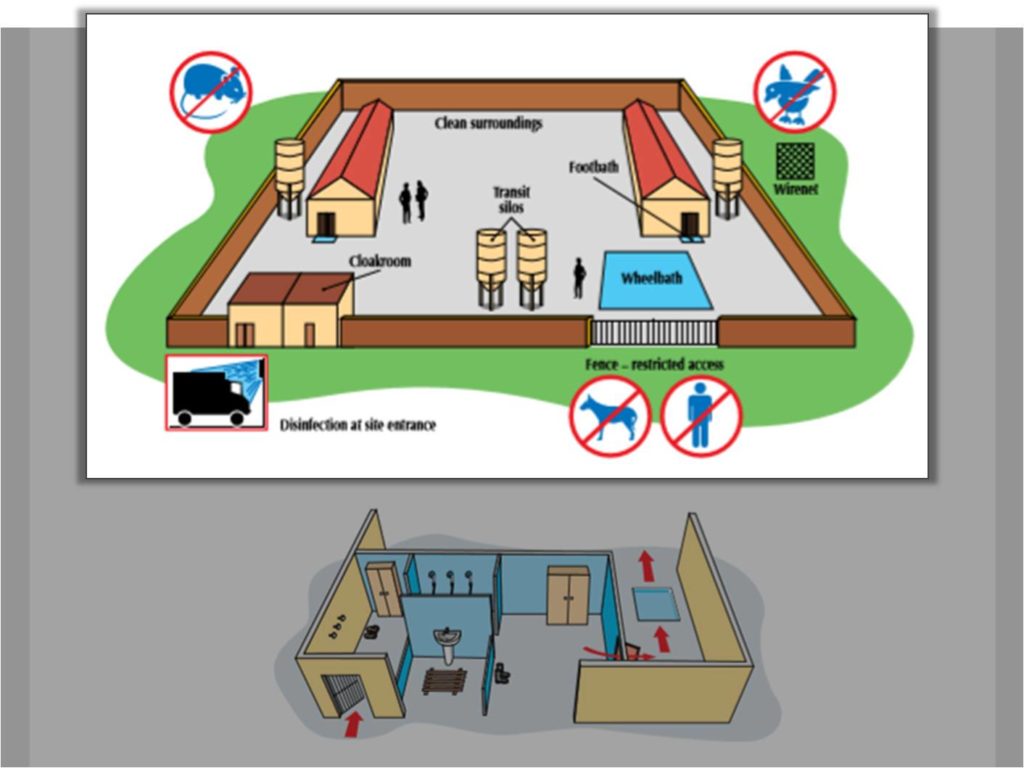

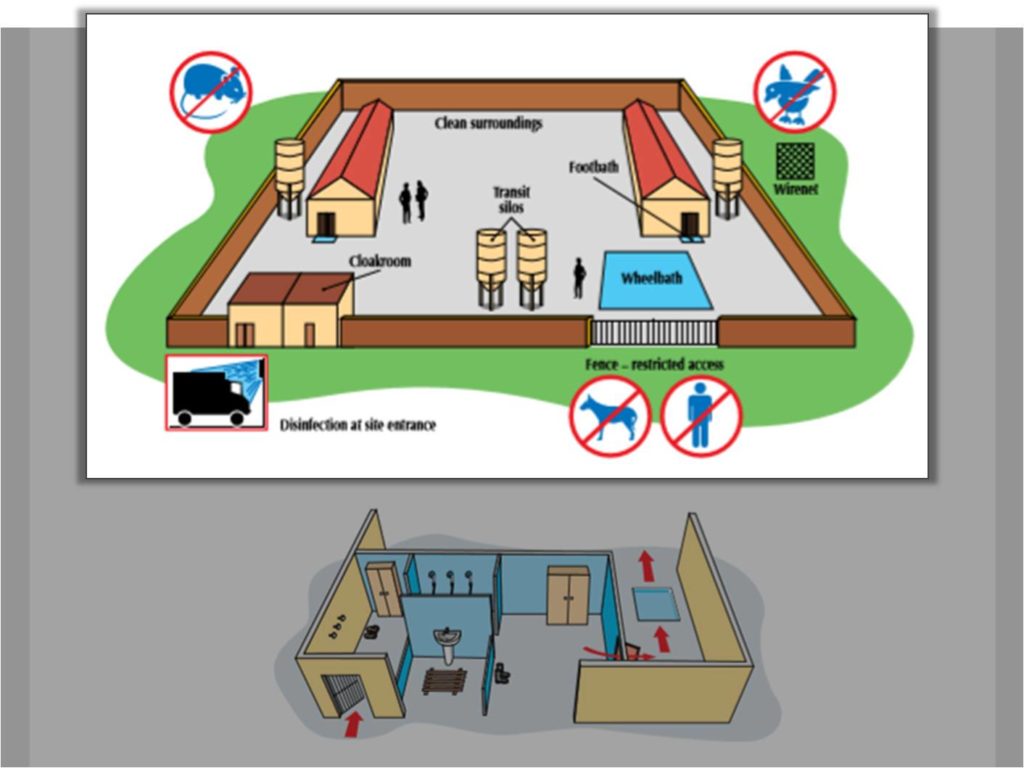

A key focus for planning your broiler farm layout should be hygiene.

Cross-contamination often occurs because of lazy thinking or critical flaws in planning.

Consider every pathway or workflow of movement around the farm and minimise infection risk.

Processes & Procedures

The single most important aspect of broiler farm management is workflow.

Controlling every functional task within the farm processes from beginning to end…

…gives you maximum chance to pick up and retain those points.

And in the poultry business, points equal profits.

Environment

Environmental control affords comfort for your flock.

Temperature, humidity, lighting, ventilation, noise, density…

…all have an impact on their well being and ability to grow.

Hospitality goes a long way to keeping your broiler flock in peak condition.

A well-kept flock make for good profits.

Buildings

With broiler farming building integrity seems to be a frequently overlooked piece in the long term profit puzzle.

Buildings that have vulnerabilities are long term business liabilities –

Not assets.

In the ‘Poultry Houses‘ blog comment above from Dr. Dhia Alchalabi (Doctor of Philosophy Ph.D. focused in Agricultural Engineering Technology from Michigan State University):

“…you must also maintain the static pressure inside the shed.” – Dr. Dhia Alchalabi

Why?

Temperature leaks, uneven distribution of heat, water leaks etc.

General discomfort for your flock leading to underweight results.

So, ridding your broiler houses of any deficiencies will lock in your profits for the long term.

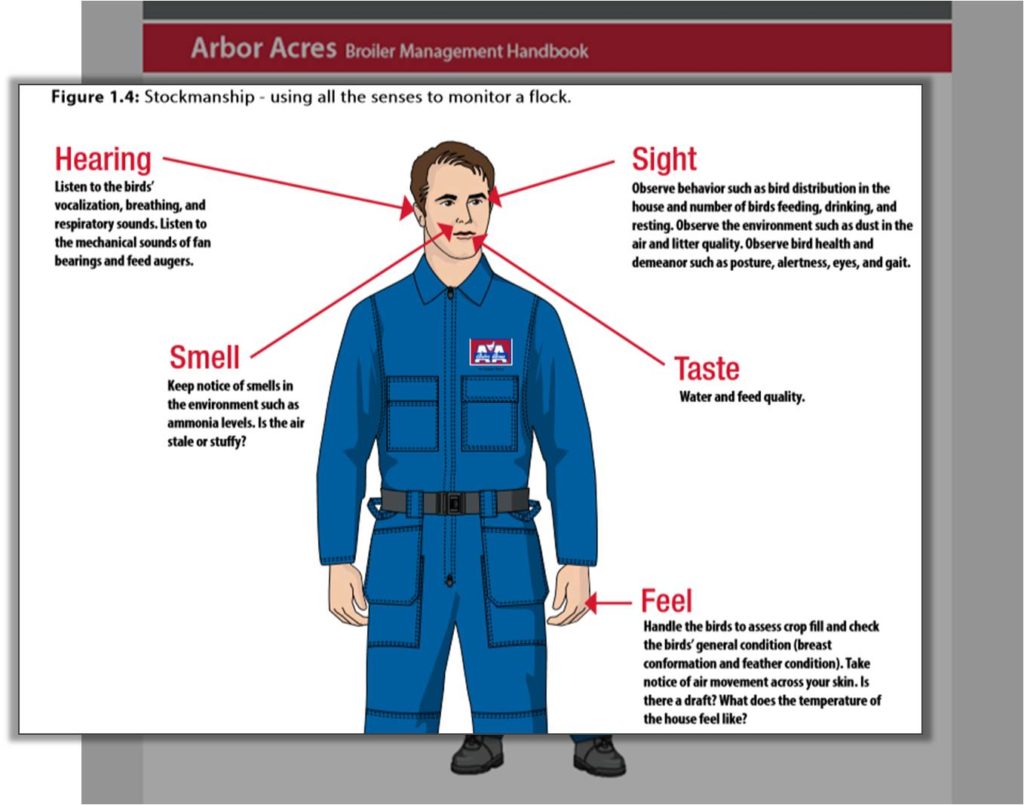

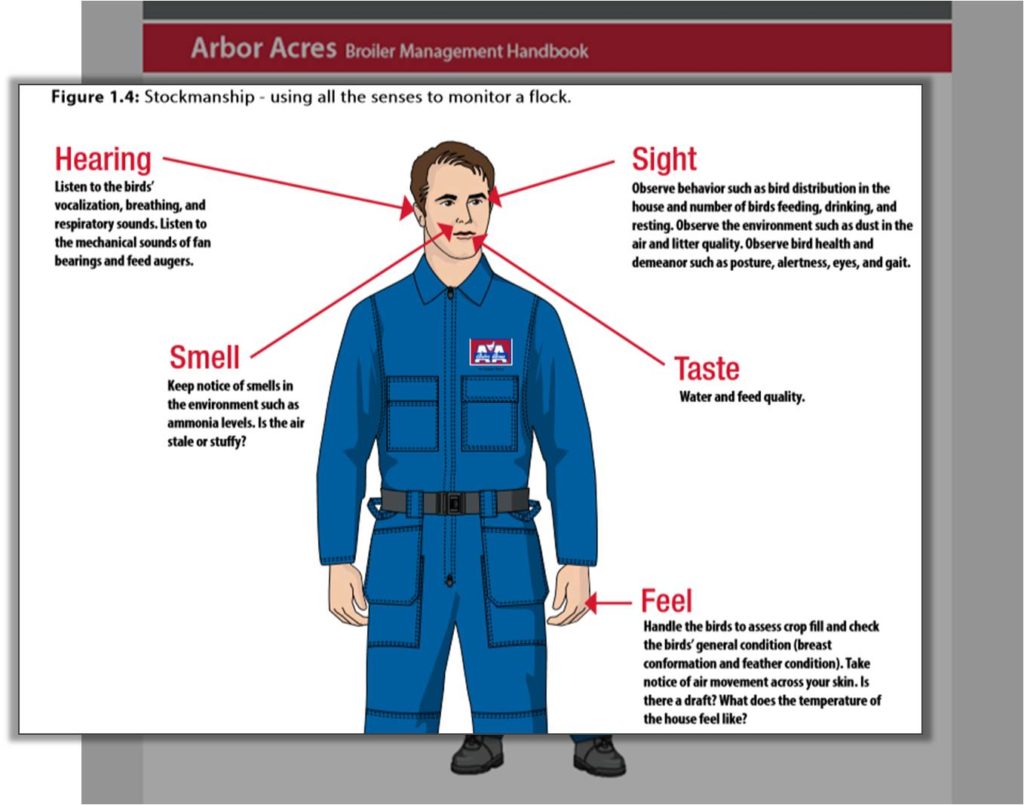

Stockmanship

The more time you spend with your flock, the more attentive you will be to their needs.

Sure it will cost you in time spent on-site, but the costs of missed signs of trouble could be much worse.

Count the cost of your project commitment against the real demands of keen husbandry.

To know your flock (KYF) you’ve got to get immersed.

Your birds could be telling you of problems ahead by something as slight as their breathing rate…

…are you keen enough on hearing and sight to know there could be something wrong?

The only way to develop this is practice…spend more time on-site.

The full 5 senses need to be engaged.

Only then will you have that feeling that something needs correcting which saves your bottom line.

Problem-solving

Having a list of possible’s and probable’s when things go wrong will give you some responsiveness…

…and timing can make all the difference when putting out potential fires.

An issue like, not eating could find its root in all types of causes:

Clearly, feed directly impacts weight…which directly impacts sales and so on…

The compact nature of the broiler cycle means a day or two of inadequate feeding can cause a slide off which you might not recover from within the 6 weeks, for example.

Daily gains all add up.

House Design

Broiler housing is dependent on so many factors:

…your chosen model, the scale of the farm, locally available building materials etc.

The house design spectrum is broad.

Innovate.

There is plenty of room for leading in new ways of thinking about broiler farm housing.

Climate, location, orientation, topography – the factors affecting your choice are too many to be exhaustive.

Research broadly.

Look locally at model broiler farms, as well as at other countries with similar climatic profile to yours.

Develop a scrapbook of feasible ideas and shortlist a potential line-up of materials and features.

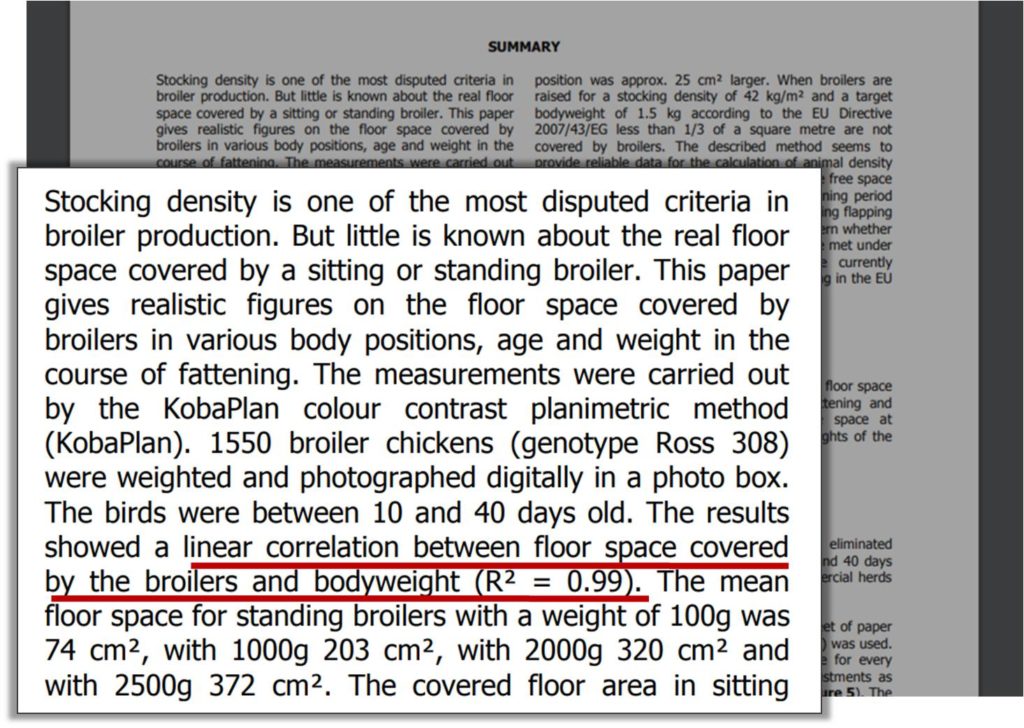

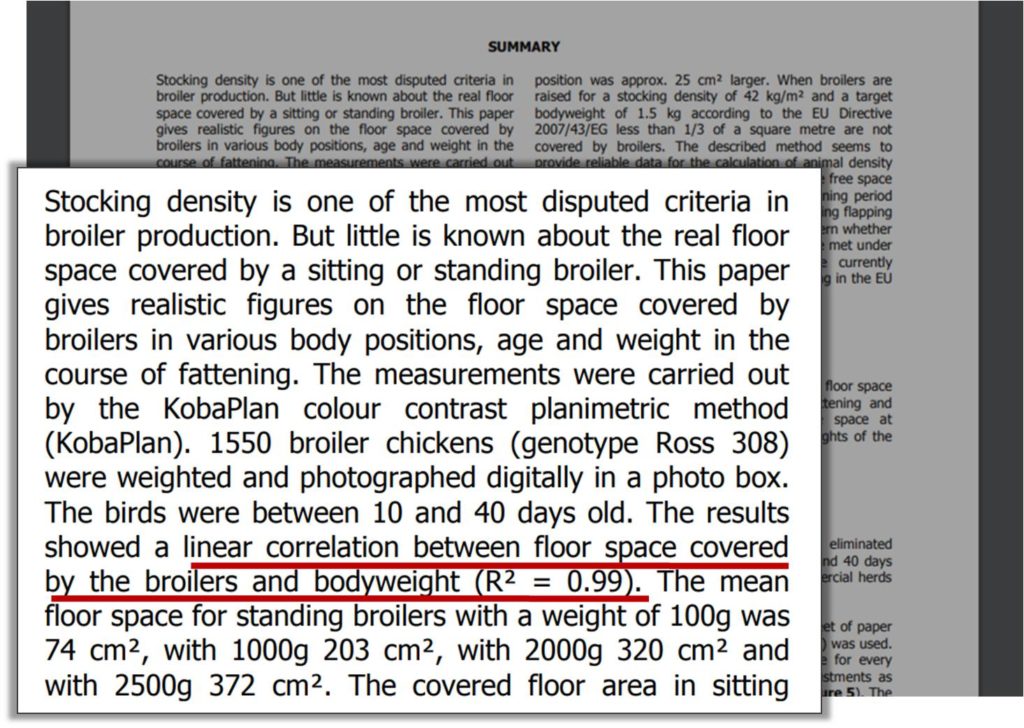

Space requirements

One practicality with broiler farming is planning space.

How tightly packed your flock is (density) influences their ability to grow as chicks into full-sized broilers.

As broiler chicks grow, their need for space also increases in line.

Planning ahead, including factoring in your expectation for farm growth, will help you provide enough to accommodate your vision.

Week 1

Receiving your new batch

Now, we are going to take a look into the critical 1st-week management of your new broiler flock.

This start very much sets the tone for the remaining weeks of the rearing period.

Preparing to receive

The very first steps in accepting a new batch of broilers are influential for the success of the cycle.

Chicks are highly sensitive, such is the nature of the young of any animal.

In between hatching and your broiler farm, each batch changes hands a number of times and become exposed to sudden environmental changes.

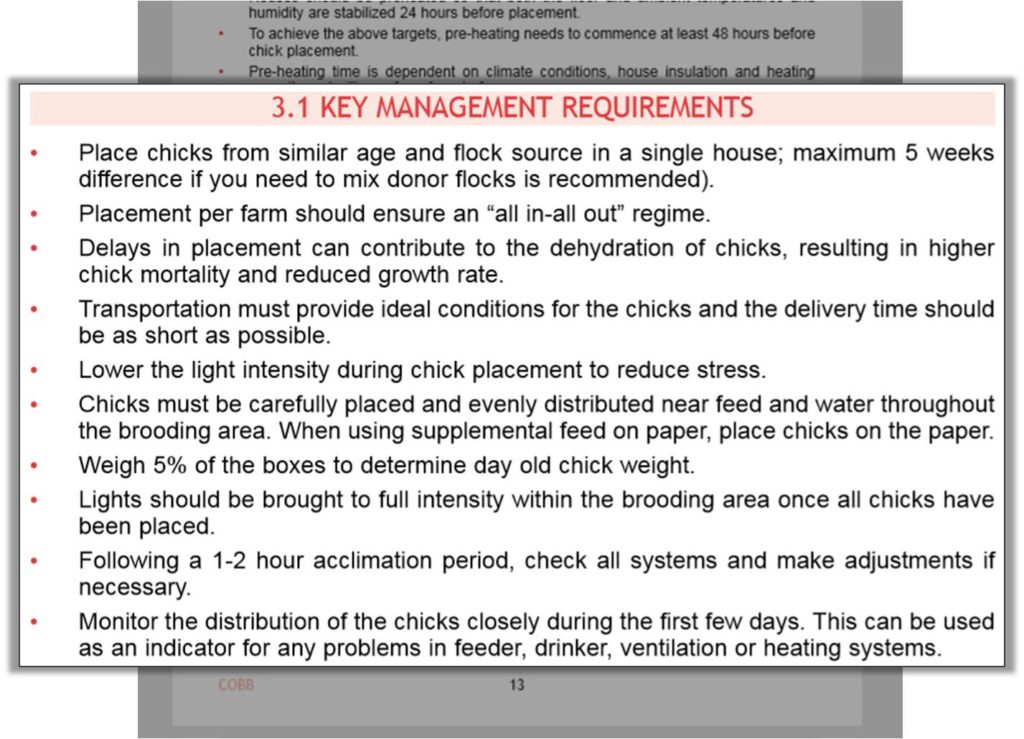

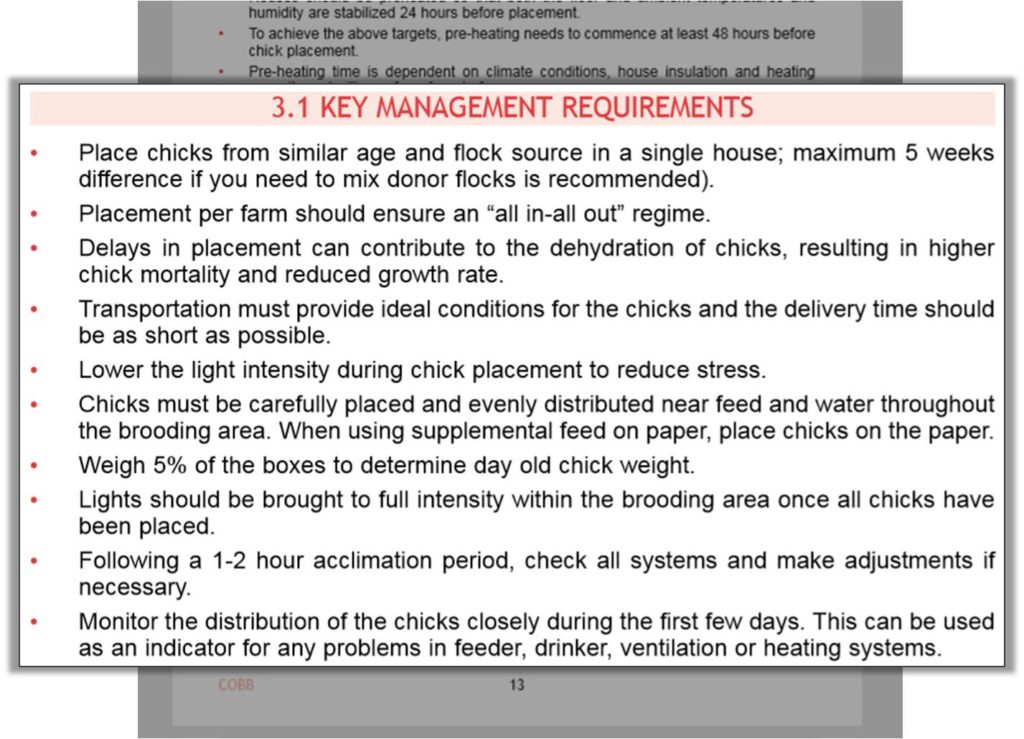

Cobb, industrial broiler breeders, advise the following farm preparation:

Again, the golden rule for survival’s sake is all-in-all-out hosting of batches.

Avoid delays in chick handling – as they can become dehydrated if not offered regular watering.

Transportation is a key link in the chain of batch handling. Vehicles must be custom fitted to maintain comfort levels of birds.

Your lighting levels, distribution of food and water, the humidity of broiler houses all contribute to the batch’s chances of surviving and growing on target.

Week 2 – 5

Raising your broilers for maximum growth & survival

It’s all about your handling here.

Once the flock is in your hands, it’s up to you what you make of it.

Fight off threats and nurture yield for maximum profit.

Rearing

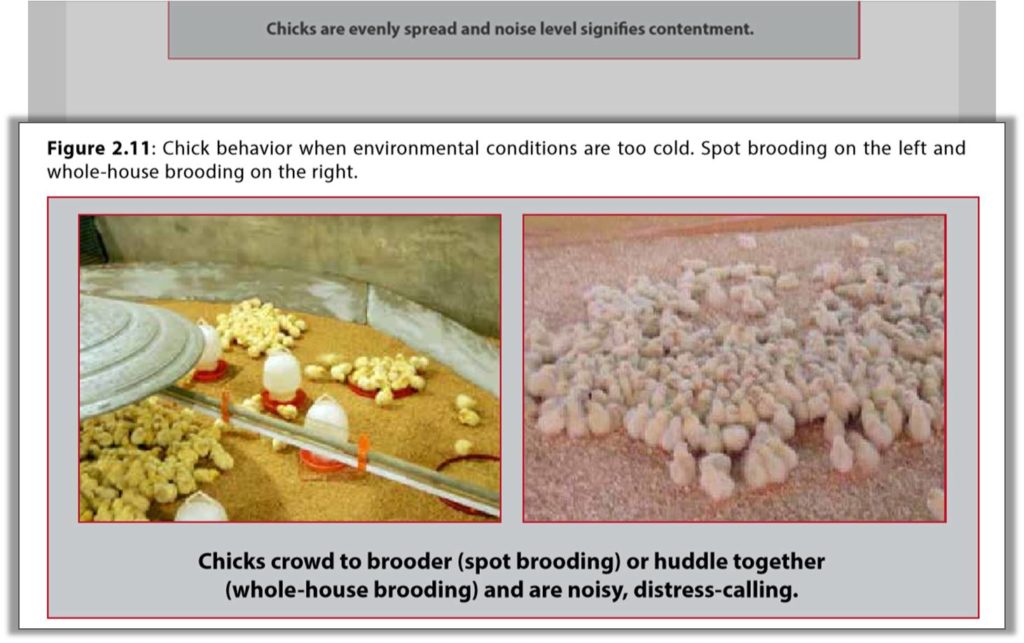

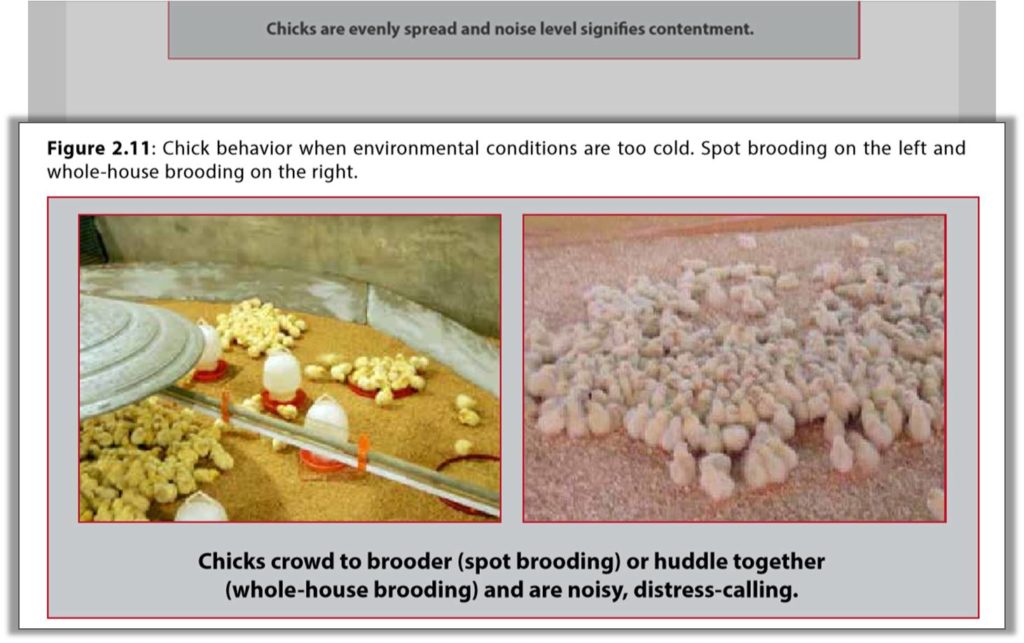

Keen behavioural observation and an experienced eye are key skills of husbandry.

Monitoring, measuring, adjusting, clipping, recording…

…broiler farm managers will issue a meticulously laid out daily schedule for farm labourers.

Your rearing schedule…

…highly detailed and precise to the last grain…

– each task adding value to the overall reward of hitting the market (on time) with a top product.

Adjusting to meet the needs of birds during changes in weather conditions, for example…

…with vigilance and agility, are key handling qualities for keeping on top of broiler farming.

Nutrition

Growth is complex, in the truest sense…

…broilers reaching their targeted size and weight depends, in part, on the availability of the right building blocks.

You need the appropriate materials in order to build properly. And enough of them.

Nutrition is exactly that.

Put another way,

…to write a script you need mastery of the entire alphabet.

Otherwise, key messages will have omissions and the purpose is overthrown.

The comparisons go on – but the message, I’m sure is clear to you.

Diet

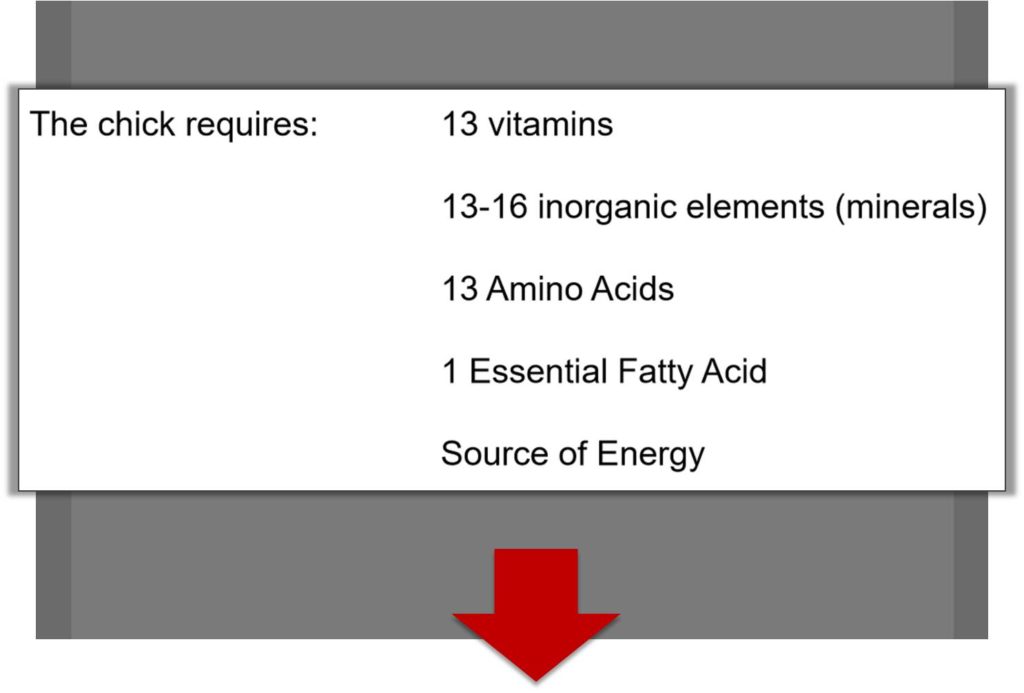

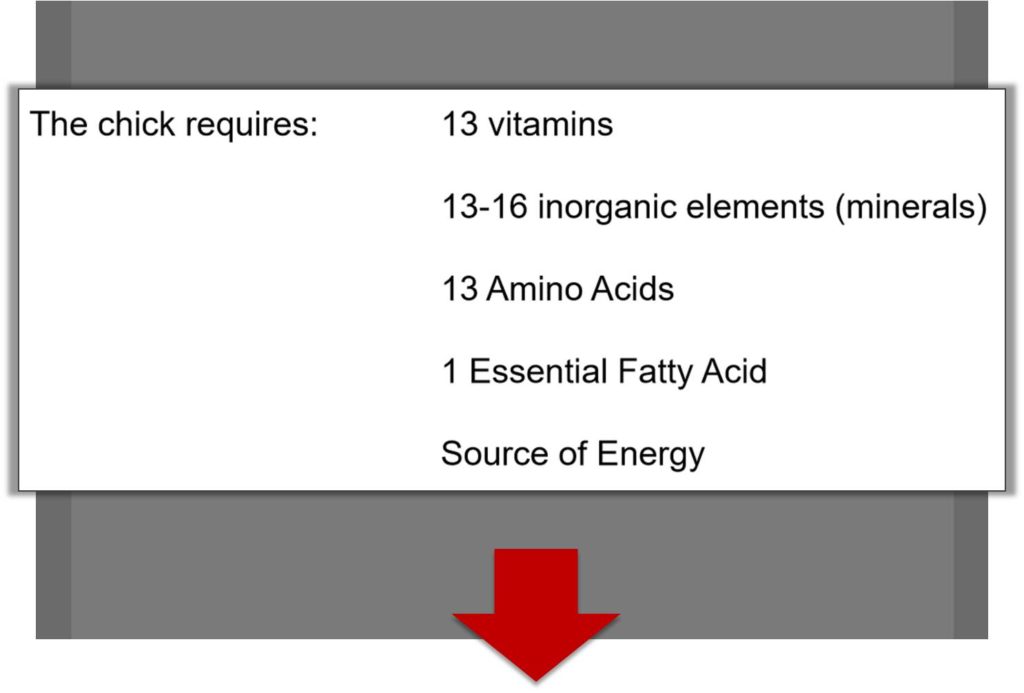

What are the essentials for broiler growth?

Well…

You get these:

…from these…

And speaking of building blocks, with muscle as our focus in broiler growth…

…we look to protein (the substance of muscle tissue).

One thing to note is you cannot force the body.

The body is naturally calibrated to use what it needs.

In other words,

You can’t keep pushing protein to add mass beyond what the body’s wiring has programmed within as limits.

That said, protein is essential to broiler growth.

The root of which are amino acids…protein building blocks.

What advice should we take on amino acid intake for broilers?

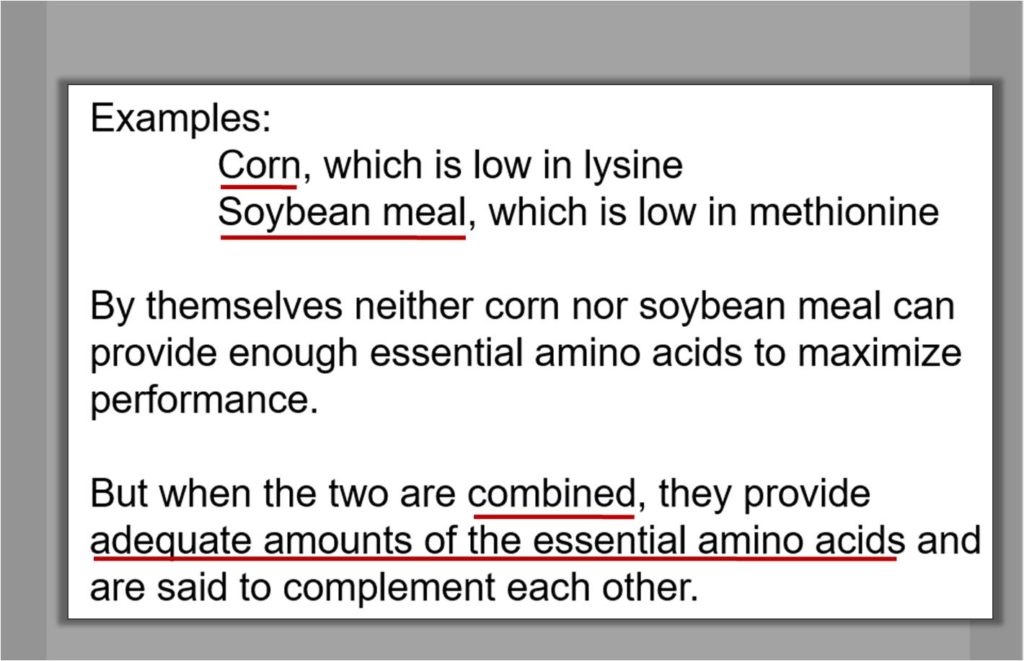

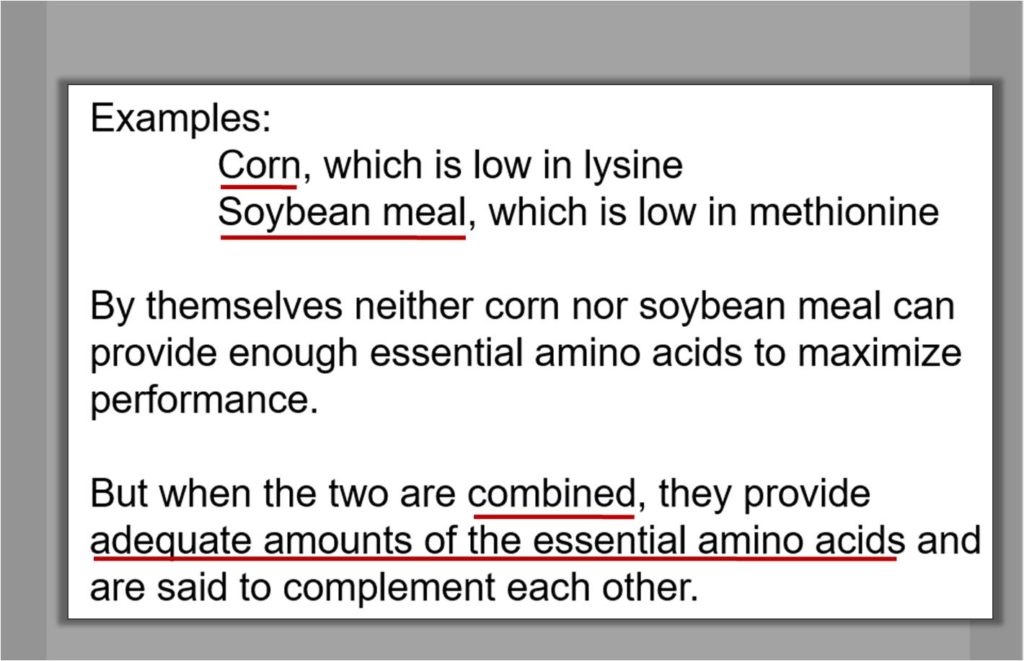

Animal or plant protein is the ideal source.

For example…

When eaten by the bird,

…the vegetable protein complexes are broken down to amino acids and are made available for the re-building program of broiler growth.

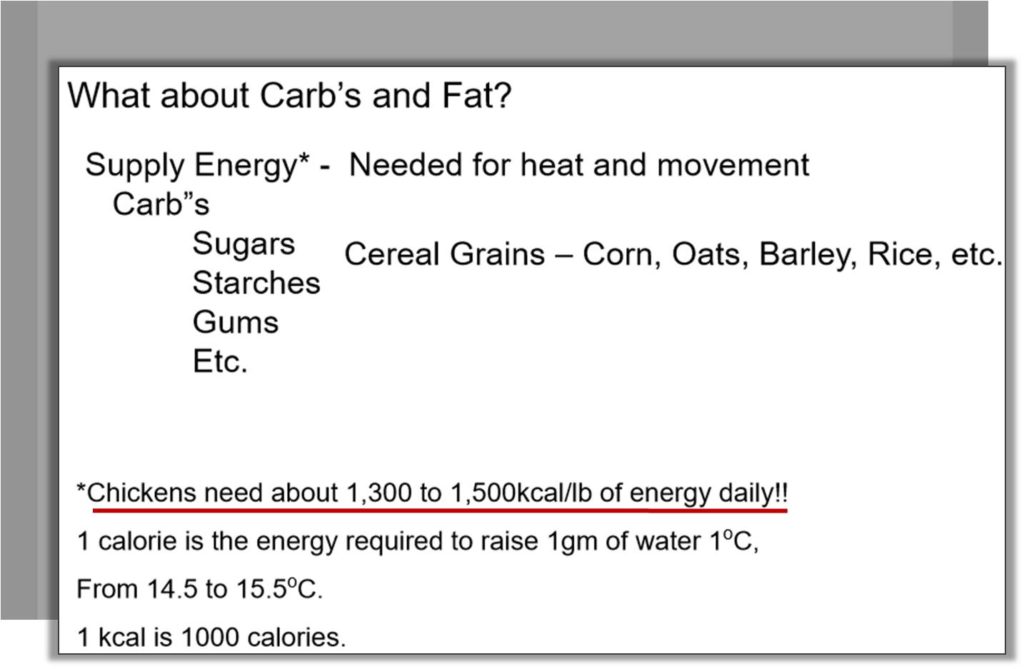

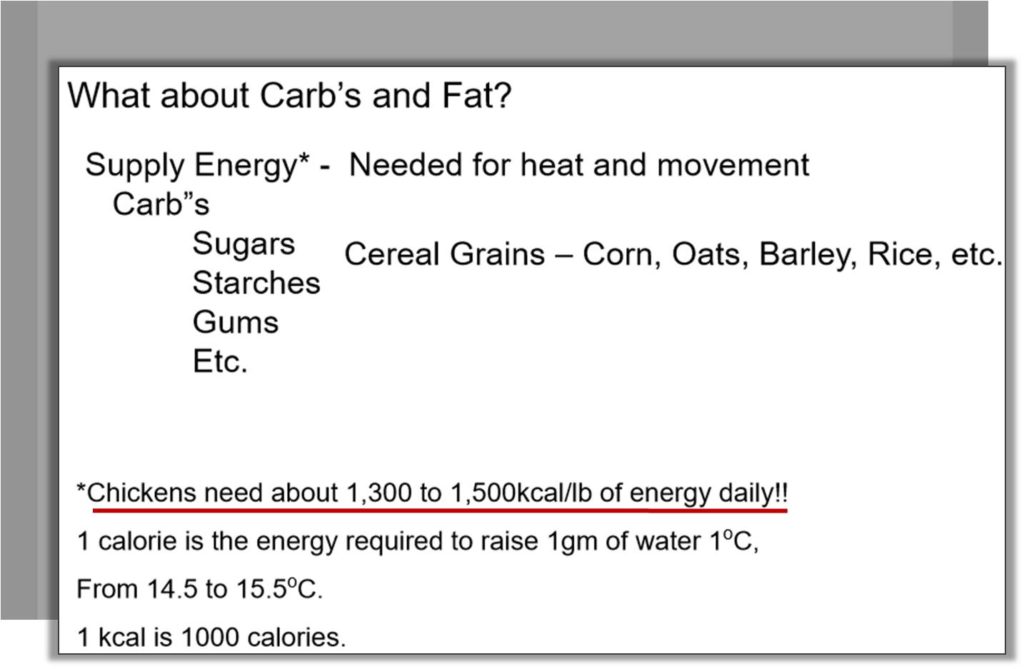

Energy

Growth is a demanding process.

It requires a lot of fuelling to power.

And all that fuel has got to come from somewhere…

It is a fine balance though, as even we as people know.

Too much energy-packed food and body fat with nutritional diseases can set in very quickly.

Also, it’s critical to note with broilers that energy consumption is a feedback loop.

To say it plain,

…give broilers too much energy-rich food and they will stop eating as much.

Reduce this and they will eat more.

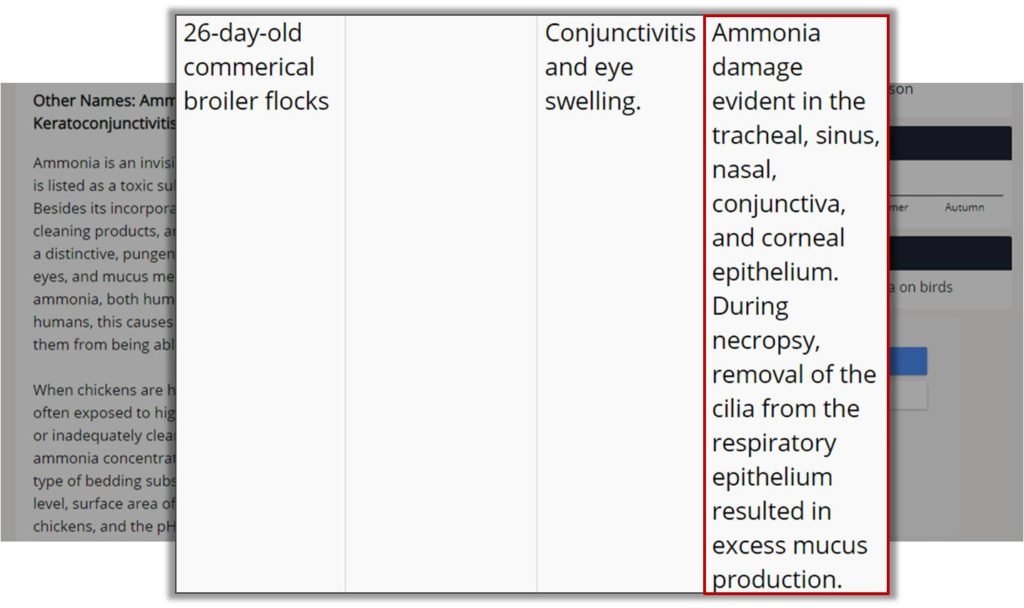

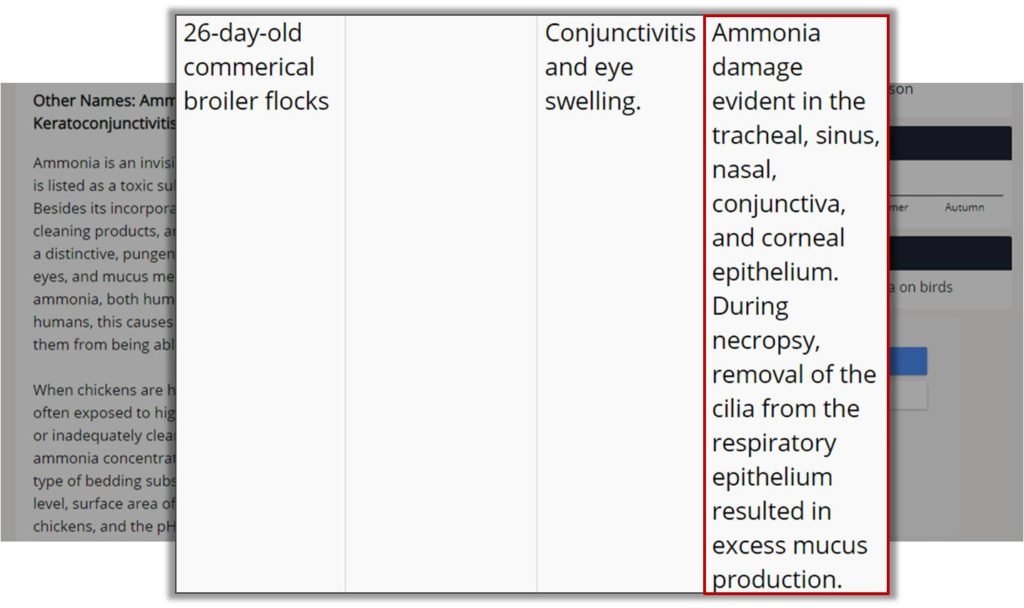

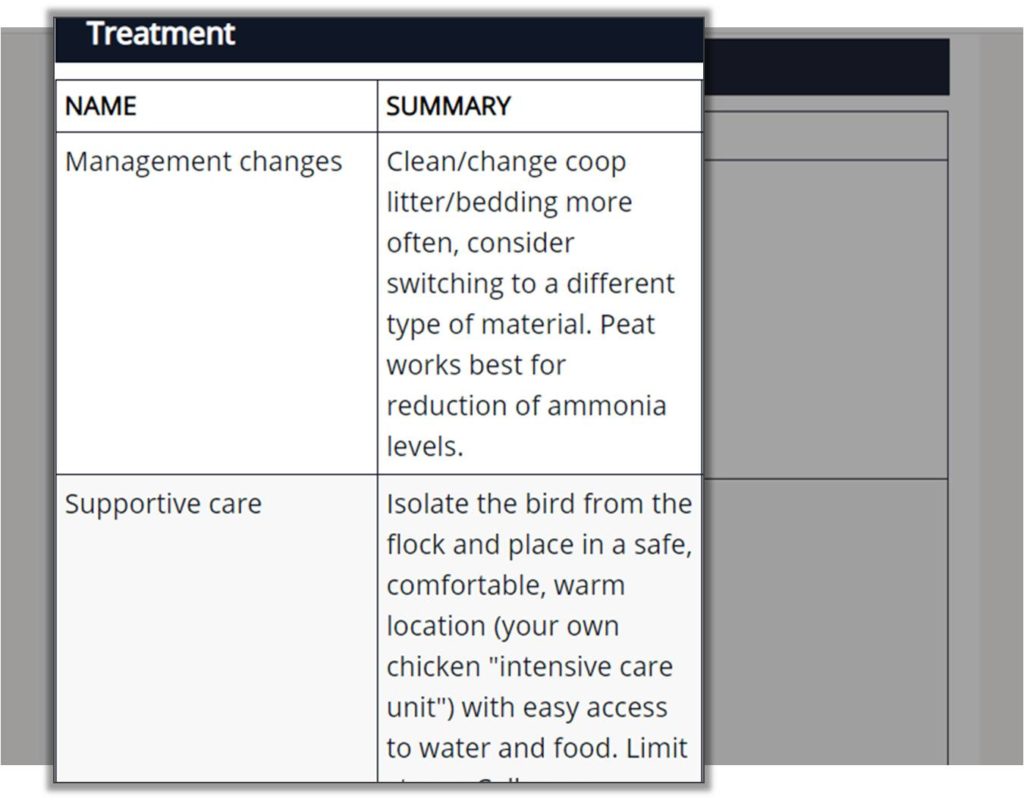

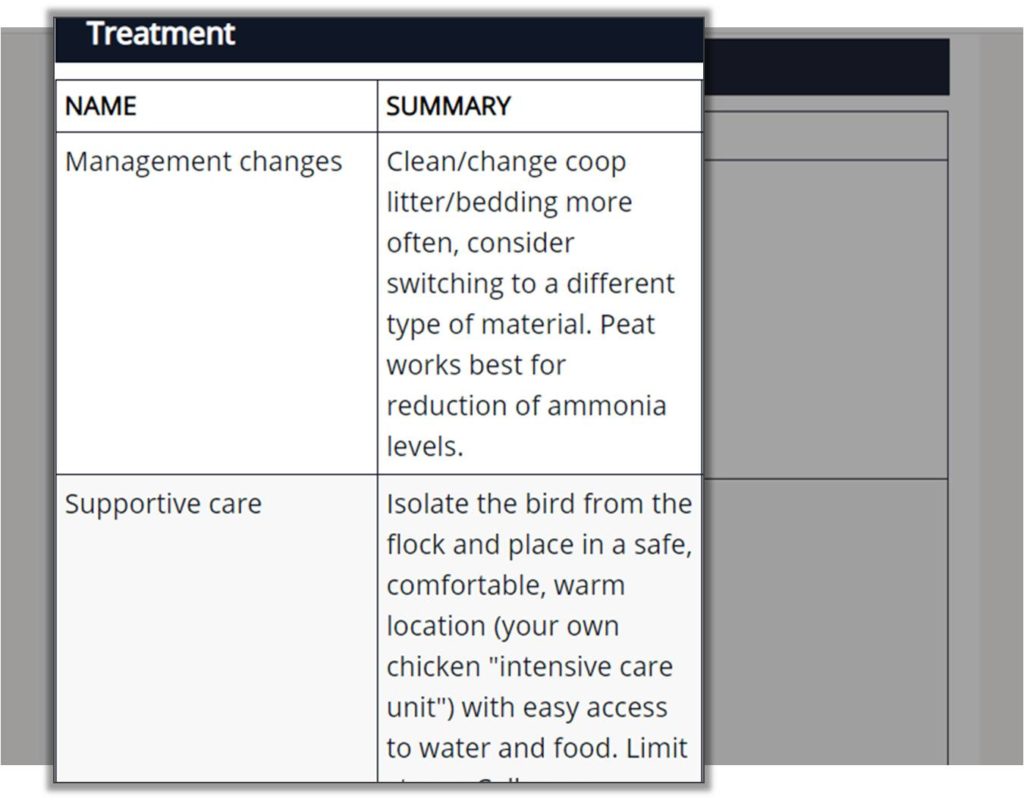

Litter

A quick associated note on waste.

If the balance on the broiler diet is too much in protein, fats etc. then the concentration of their urea and consistency of their faeces accelerates litter rot.

This can have devastating effects on the health of their feet – producing chemical burns and bacterial infection.

Also, breathing problems, swollen eyes and overproduction of mucus in the nose and throat – even blindness.

Be vigilant for litter hygiene.

Treat immediately.

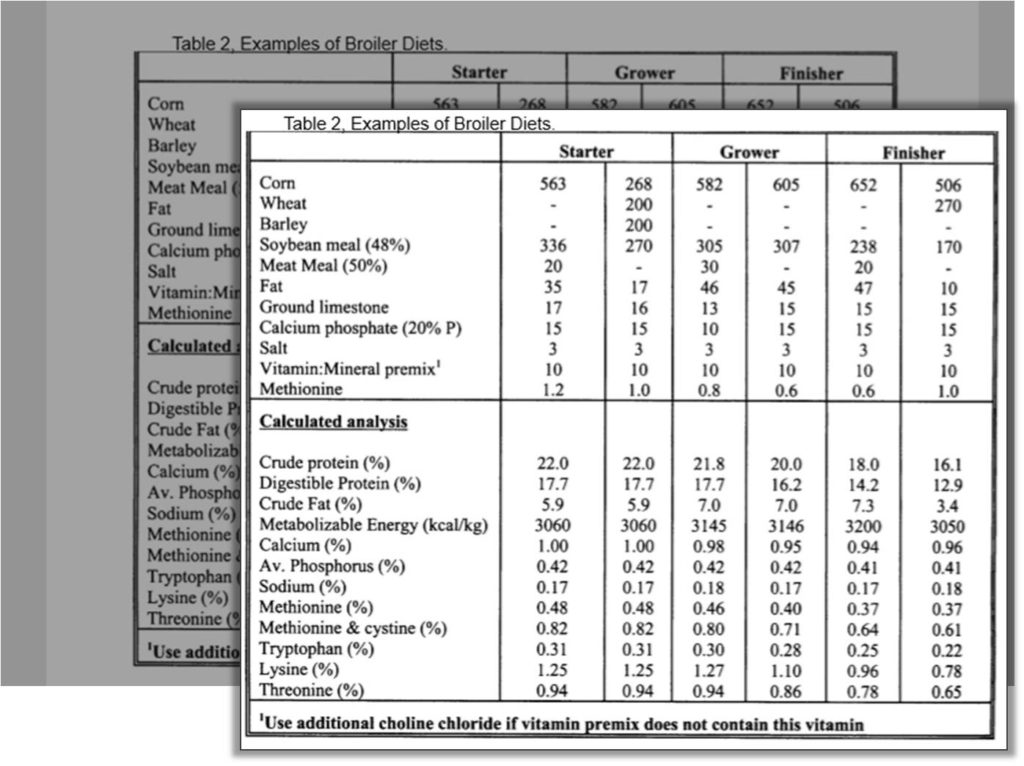

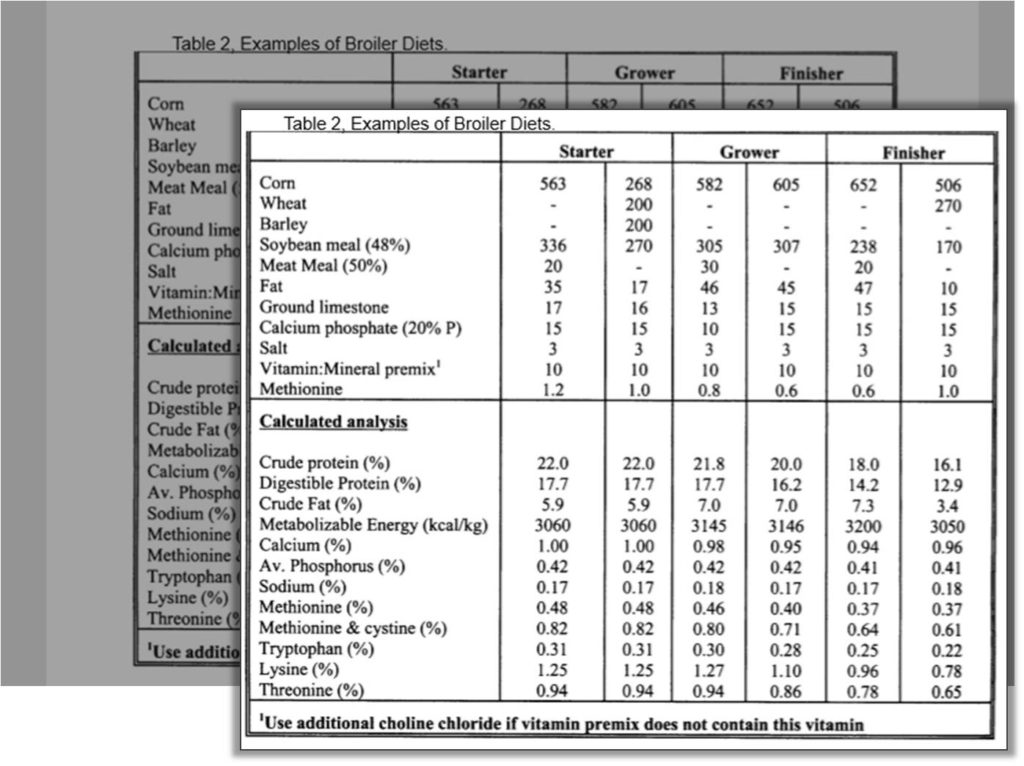

Feed ingredients

Want a look at an example broiler diet?

There’s no right or wrong way to do this.

It’s a balance.

Preference and palate have a lot to do with it too.

But so long as you are sure the contents of the diets match the profile of the nutritional need of the birds,

…you should experience good intake and conversion.

Swapping in one food source for another in a like-for-like fashion should (in theory) produce the same, if not similar results.

But ‘practice’ is the only real way of making sure.

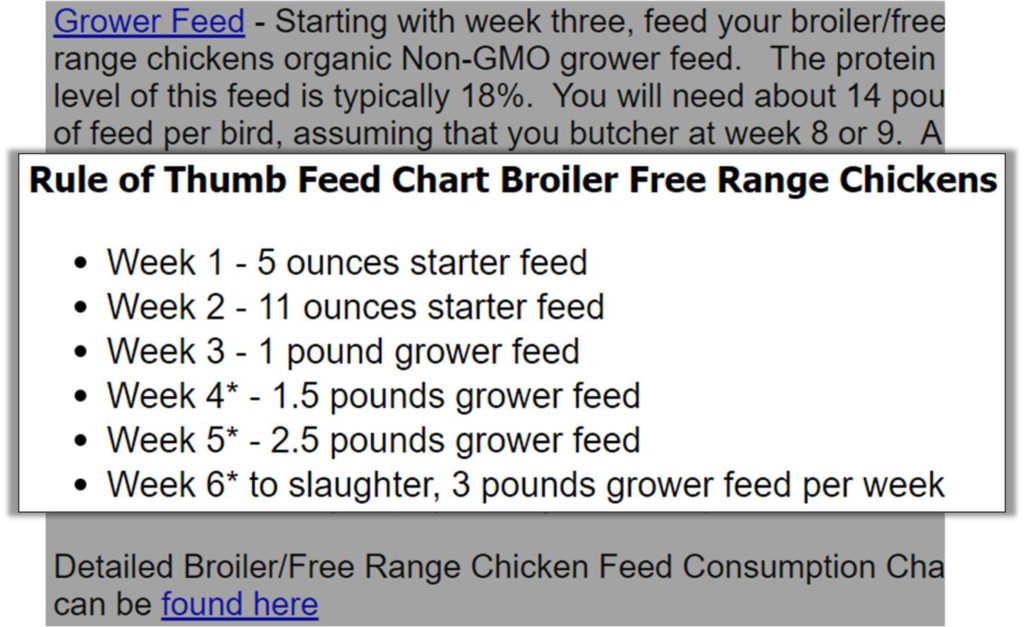

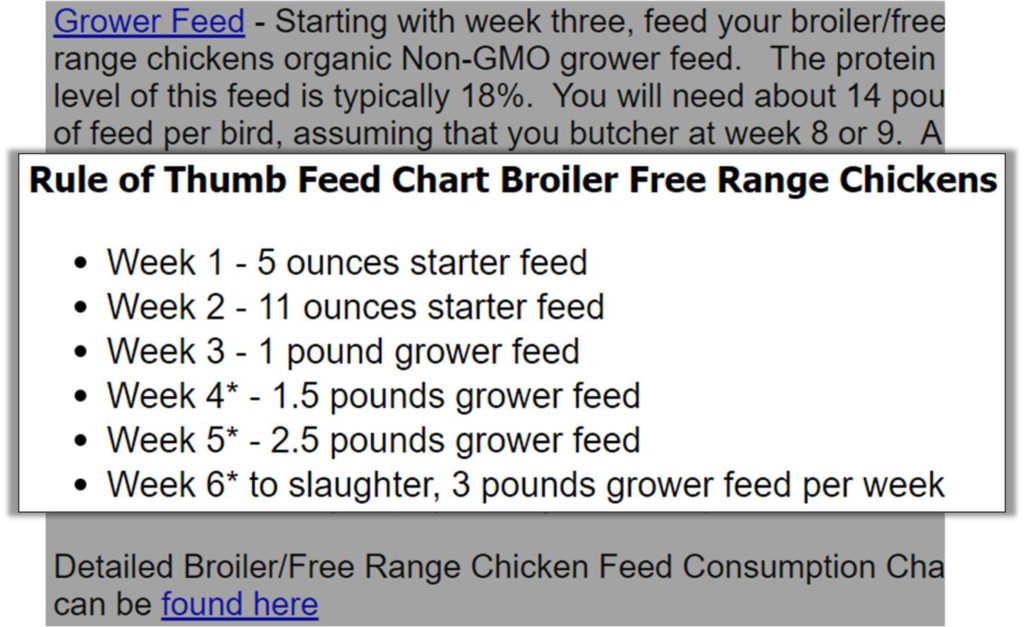

Feed at different phases

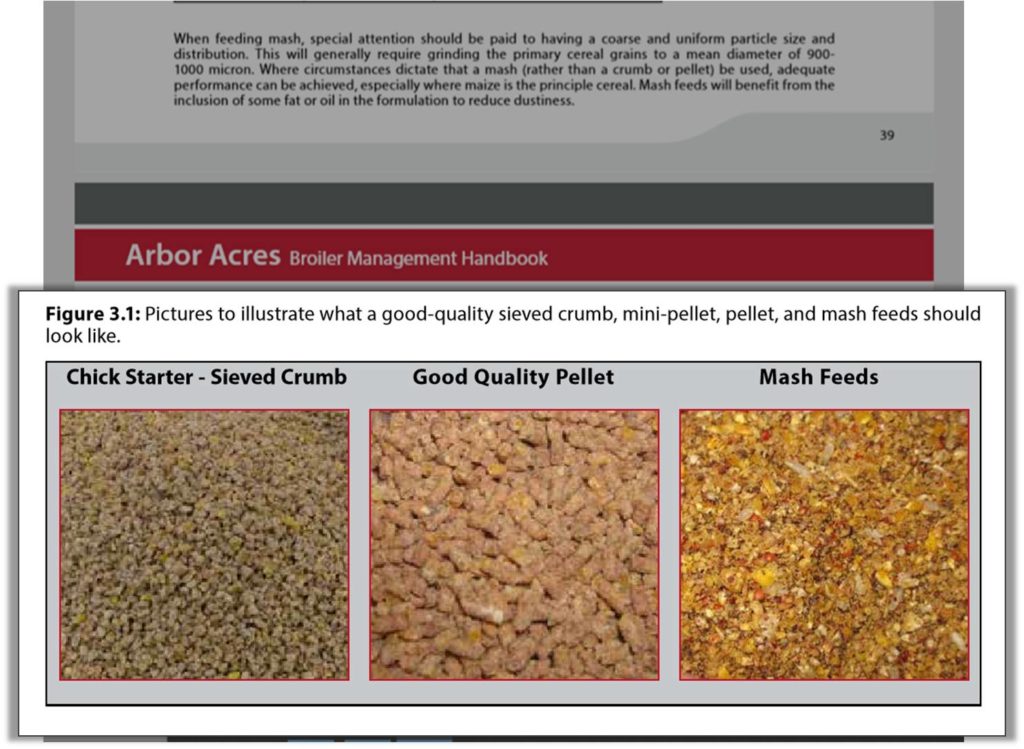

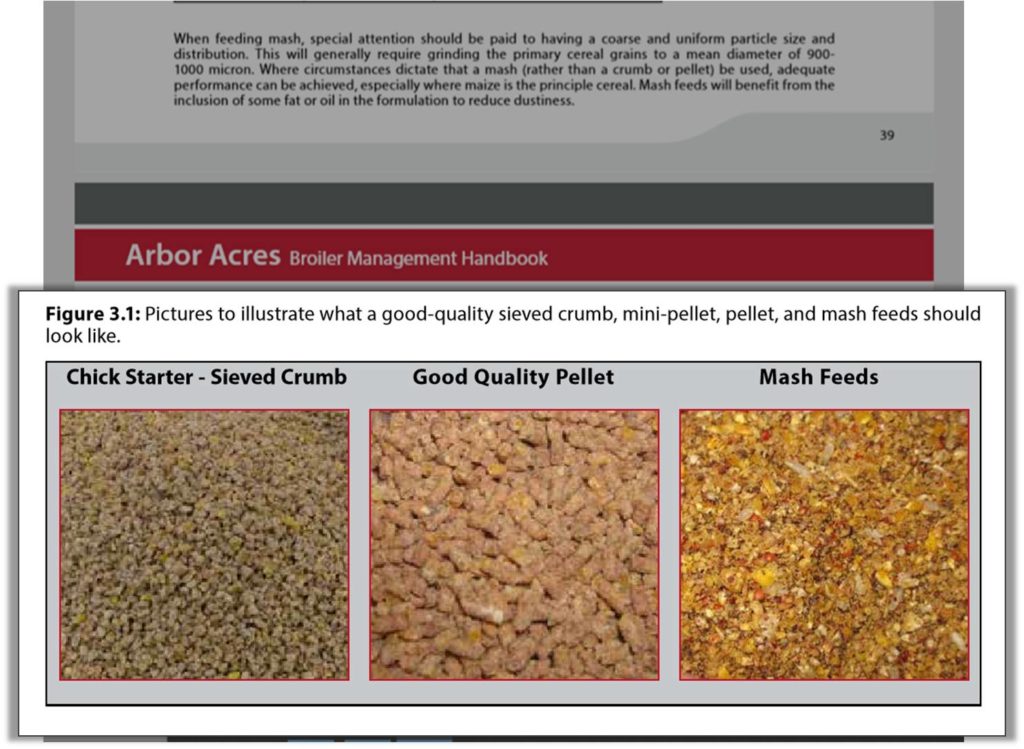

Size of food particle is a key feature in getting your broilers to their target weight destination.

Volumes of feed intake will vary at each stage of growth throughout the rearing period.

But also, ability to take in different sizes of feed changes with age.

Physically, particles too big will neither be practicable nor appealling to young chicks.

And mash powder might simply be wasted by larger broilers leading to lost profit.

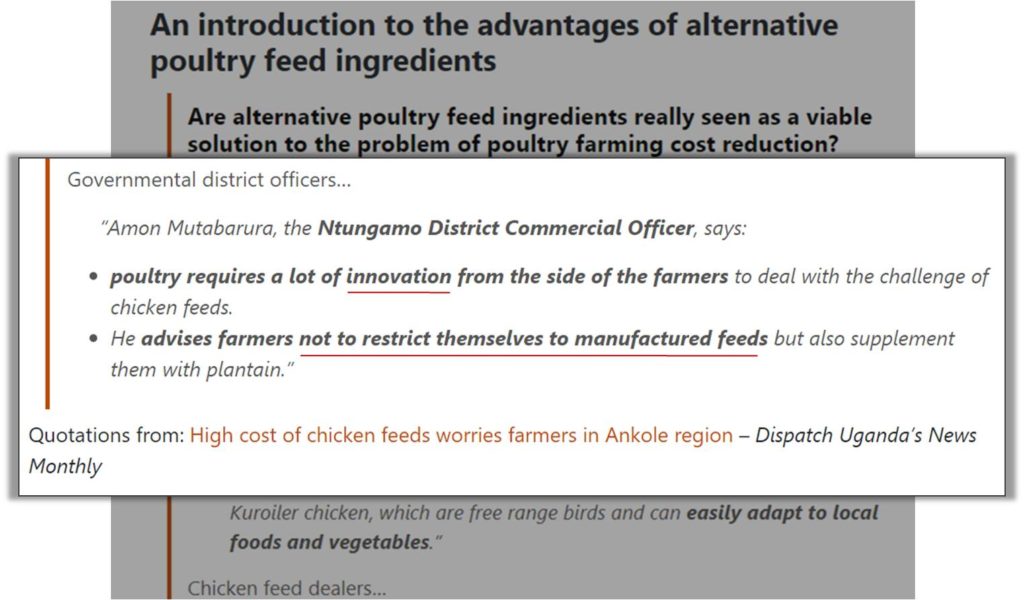

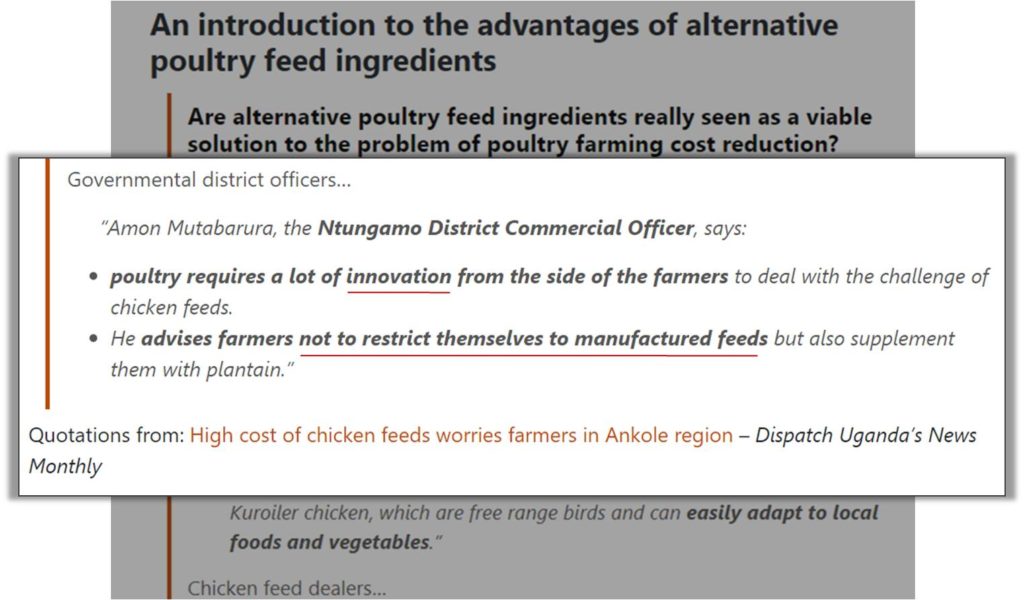

Cost and alternatives

Remembering the heavily weighted contribution of poultry feed to the overall cost of a broiler farm…

…finding alternative food source ingredients in your locality that are either cheap…

…or better – entirely free…

…is a great way of widening your margin of profit.

Governmental officials are mounting their support behind alternative ingredients for poultry feed.

In this way, they hope to stimulate start-ups and bolster their local economies.

Farmers who earn more, grow.

And so will their communities.

Feeding & Watering

Feeding and watering are critical to your broiler farm for three reasons.

- They are the key drivers for growth.

- They are the key drivers for cost.

- Nowhere to hide – you feed and water them every day until slaughter.

Get it wrong and your profits will ebb away.

It’s an issue of training.

Training your birds from day one on to the feeding and watering apparatus will set them on the right track.

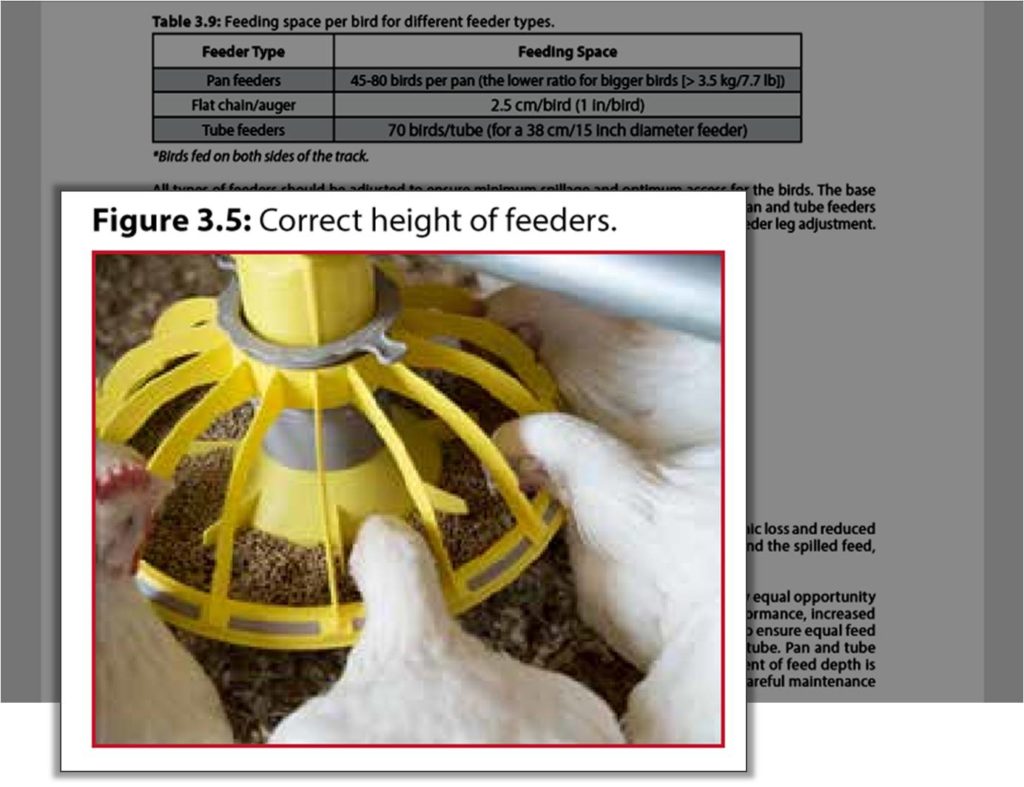

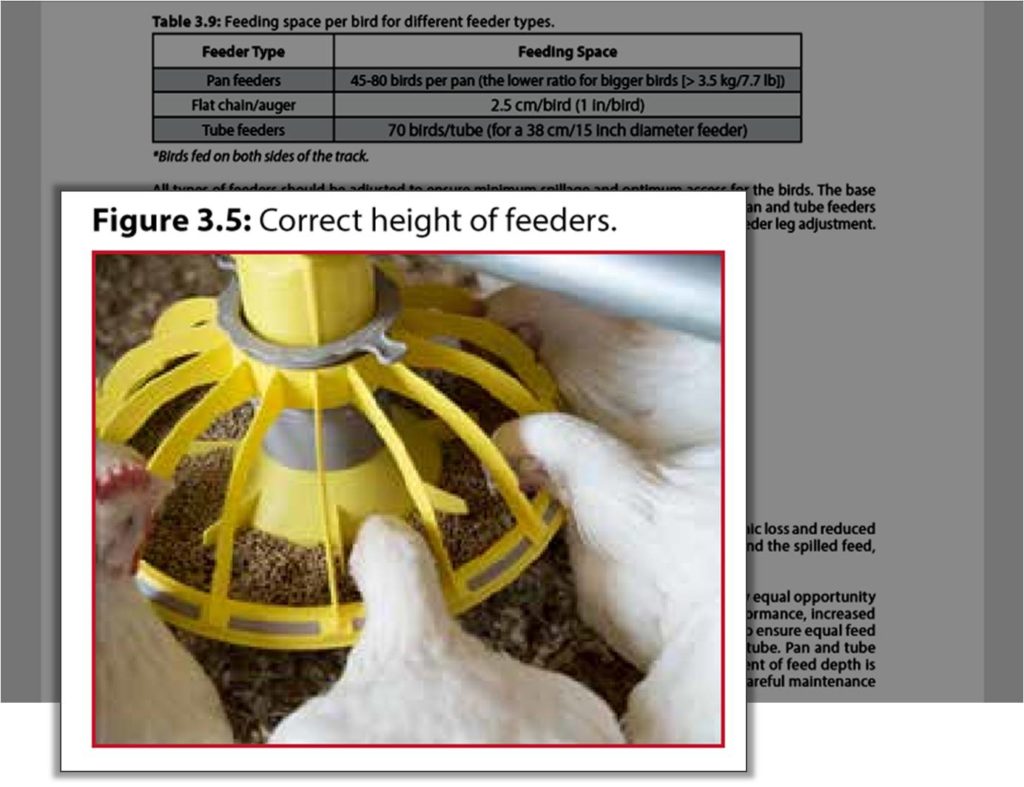

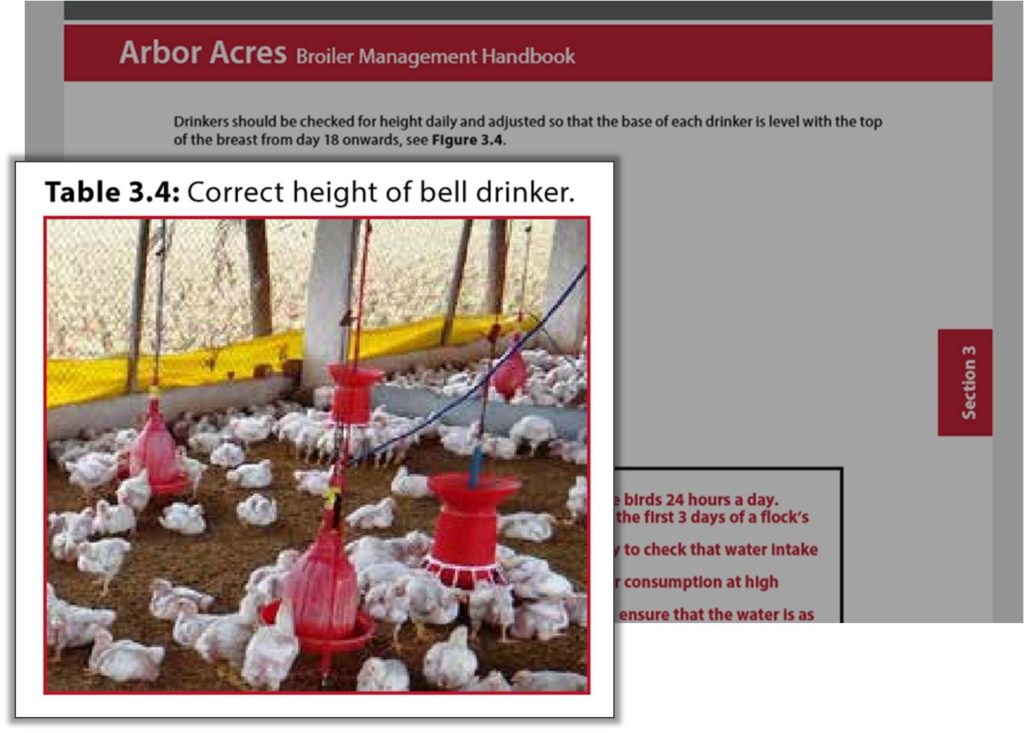

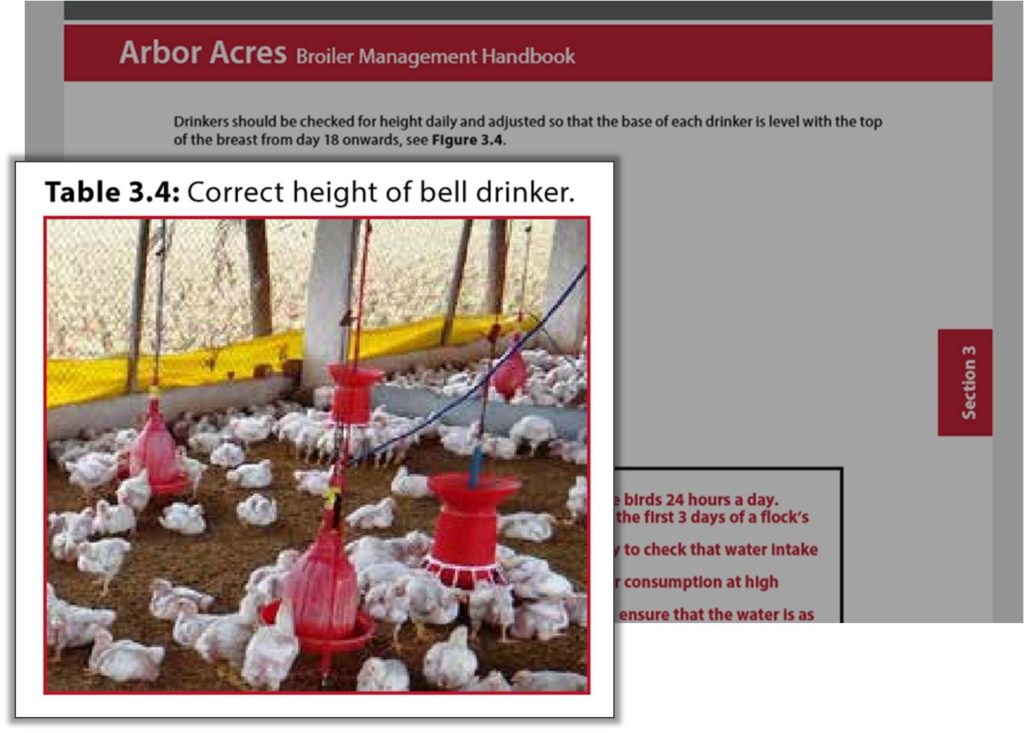

As they grow, you’ll need to be careful to adjust the:

- height,

- distribution

- set-up of your…

…feeders…

…& drinkers…

…to match the physical range of your growing birds.

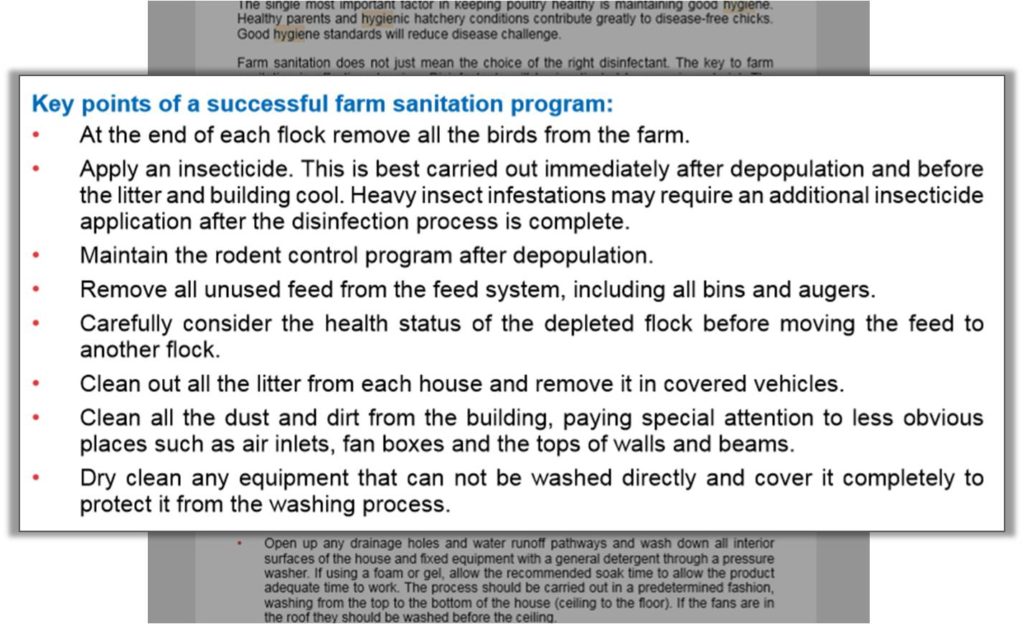

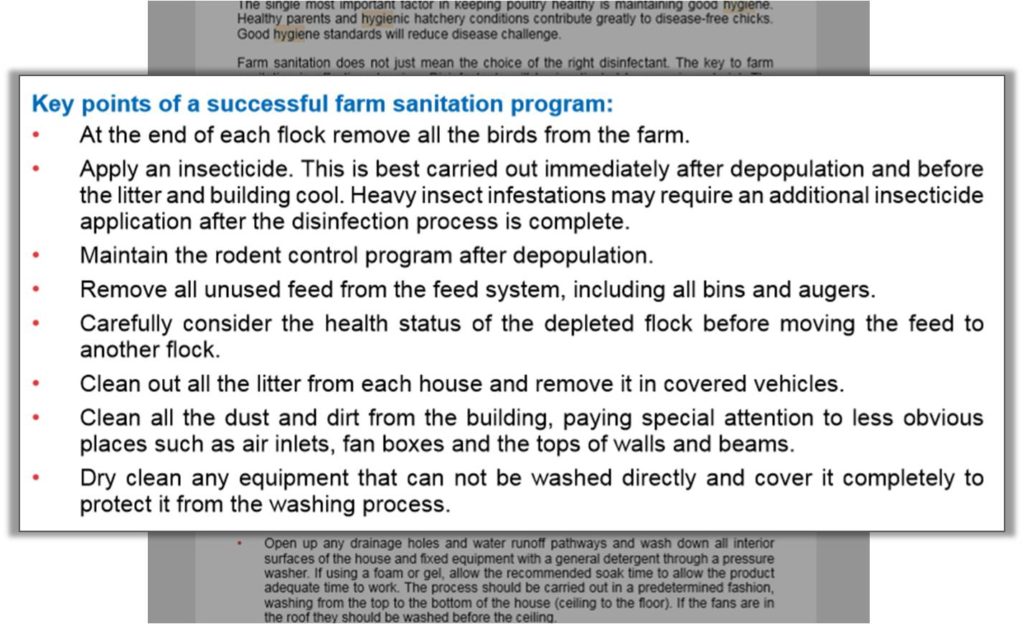

Health & Hygiene

Contamination is the buzz word here.

Prevention is better than cure as they say.

If corruption breaks out among your birds, it can threaten the entire yield of your farm.

Take stringent measures to keep sanitary conditions.

Combating infection with workflow planning

Generally, there are two approaches to stamping out disease on your broiler farm:

- operational care

- site cleanliness

From the list above, taken from the Cobb Broiler Management Guide, you could group the sanitation measures into the following categories:

- things to remember

- things to administer

- things to keep out

- things to clear out & empty

- things to examine

…just some of the fundamentals of keeping a healthy environment for your broilers.

Regular cleaning, spraying down and washing of vehicles and personnel prevent occasion for breakout, should an infection arise.

Disease and health

Parasites, respiratory tract bacterial infections, viral attacks are all common threats to a poultry flock.

Once contracted,

…they can spread like wildfire and bring the whole operation down with little else you can do but fold.

Vaccines are the answer for many.

However,

…the long term immune burden on people from the many vaccine programs they are indirectly exposed to, due to the meat they eat presents a significant global immune danger.

A cocktail of interference at an immune level over many years, from many sources can trigger serious problems.

In light of this problem,

…some studies in recent years have been commissioned to look into the effects of natural or herbal based medicines in broiler farming.

Like this one:

This quote above unveils the growing resistance poultry parasites are developing to man-made drugs.

Whilst the drugs are the best inventions we can throw at the intruders, created within nature is a far more effective front line.

The likes of oregano, garlic, neem, aloe, green tea, tumeric and other herbal combinations present a far more complicated and therefore…

…complete array of protection for your broiler birds.

The key here is that the bird’s body is already equipped with an immune system. A highly specified military-like response mechanism to deal with external invasive threats.

Feed the birds with a naturally occurring range of herbal food sources.

Like the ones mentioned.

And your broilers bodies will assimilate the substances provided into the necessary ammunition and force to overcome many major threats.

Growth & Fattening

Each breeder will advise their own estimation of broiler growth.

Often, broiler growth charts like this one give you all the metrics necessary:

From the information above you will be able to work out the potential market price fetched for each bird…

Also, the feed necessary for achieving the projected growth.

Take the cost of the latter away from the former and you have your broiler profit.

Growth rate

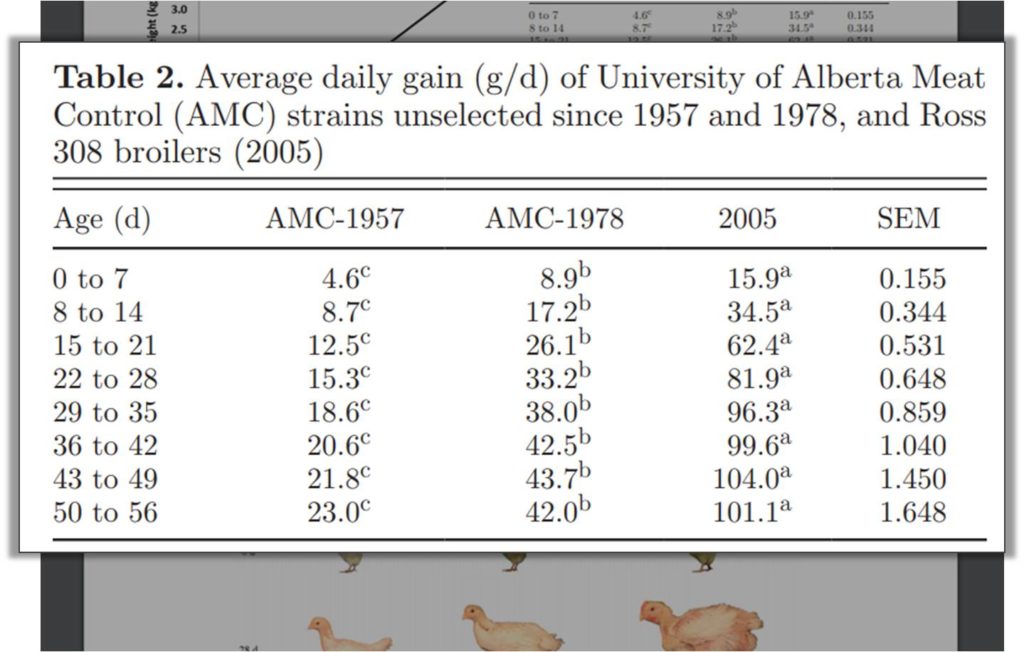

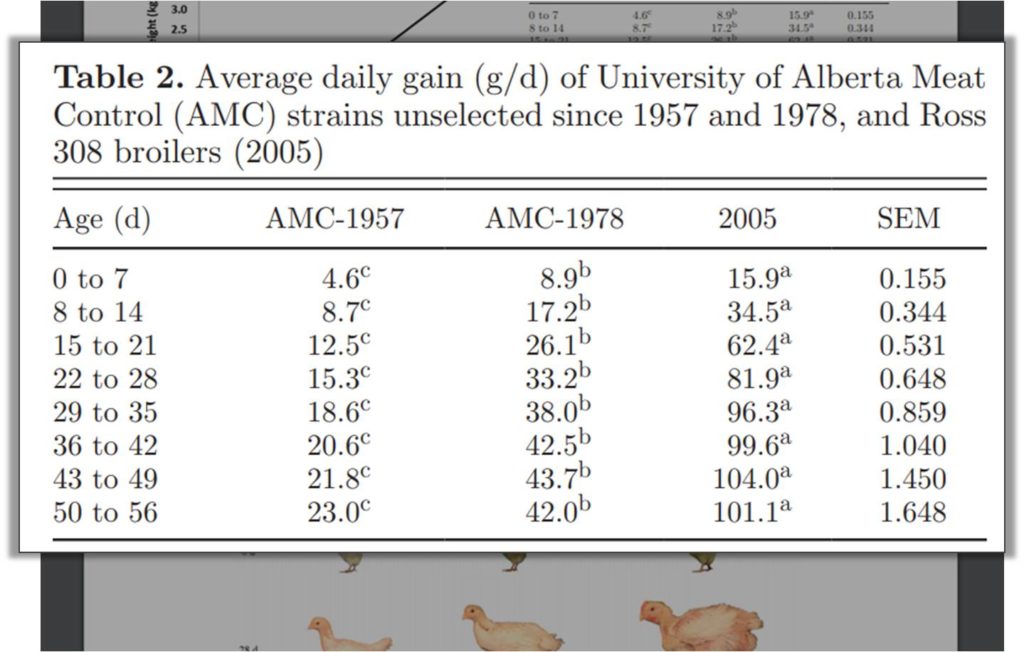

What is the typical growth rate of a broiler bird?

Taking a look at a table like this one:

You can see from the figures above that the modern strains double size and weight between weeks 1 -2.

Thereafter, weight gain is about 33% from weeks 3-4.

Then, a reduction in growth rate to about 20% increase for weeks 4-5.

Lastly in the following two weeks, the growth rate drops to about 4-8% per week.

There simply comes a point where holding on to the birds is no more profitable.

They begin eating more than they gain in weight.

The cost is loss-making.

There is a sweet spot with going to market.

Record keeping

Record keeping within your poultry farm provides a benchmark for you.

For the batch you are handling at any one time, you should always have a written reference for their condition or environmental factors.

Viewing such records keeps your progress in sight.

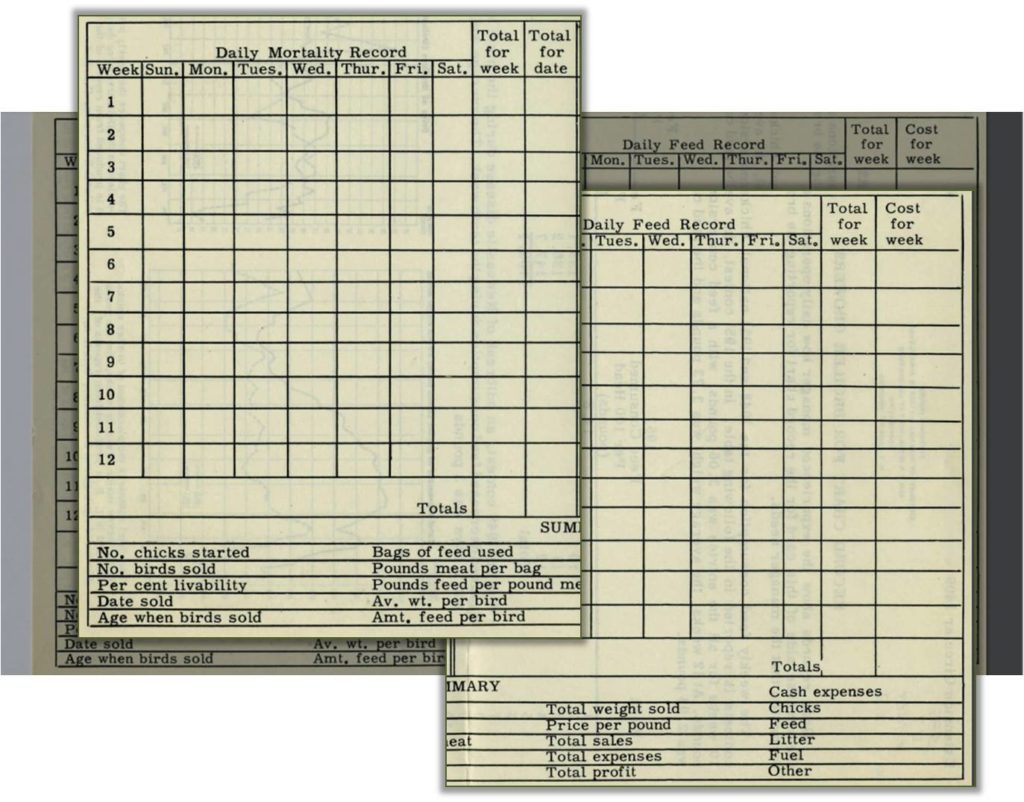

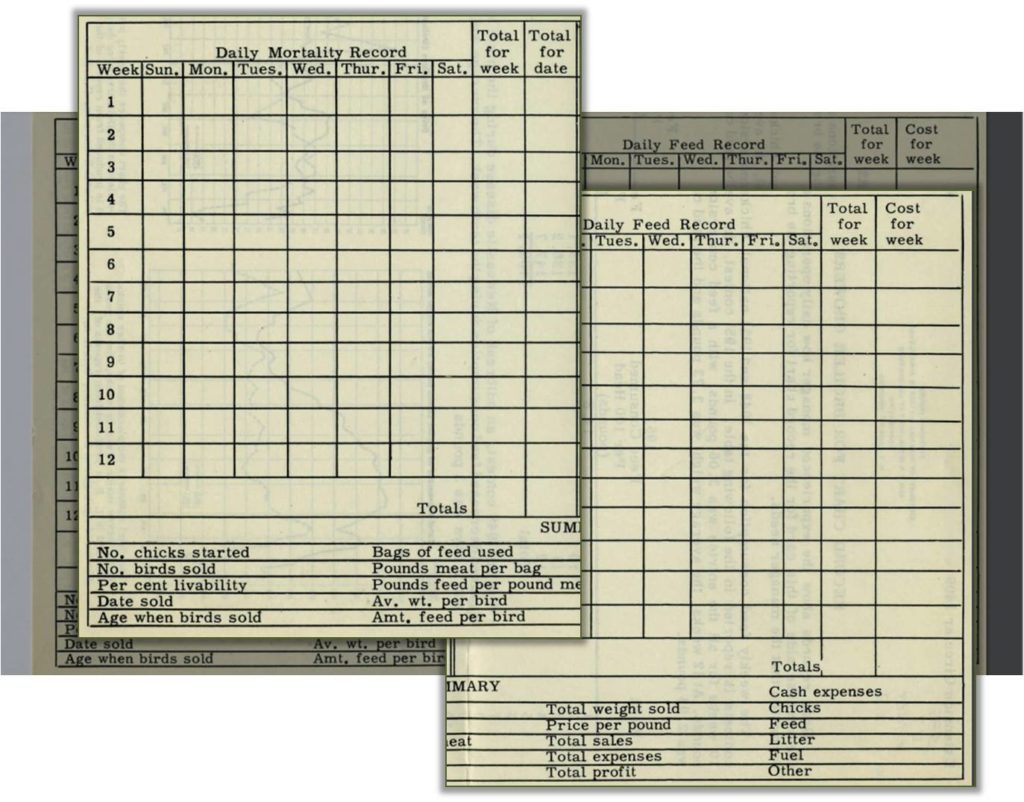

Take this paper logbook from the University of Nebraska-Lincoln.

Look at the detail!

Looking closely, we gain real insight into the main measures used by broiler farm for monitoring performance progress:

- Daily

- mortality

- feed consumed

- No. of chicks started

- Breed

- Pen or house no.

- Dates started

- Hatchery

- No. chicks started

- No. birds sold

- Per cent livability

- Date sold

- Age when sold

- Bags of feed used

- Pounds of meet per bag

- Pounds of feed per pounds of meat

- Average weight per bird

- Amount of feed per bird

- Total weight sold

- Price per pound

- Total sales

- Total expenses

- Total profit

- Cash expenses

- Chicks

- Feed

- Litter

- Fuel

- Other

Key metrics for analyzing the performance of ANY broiler farm.

Week 6 (target week)

Getting your broiler flock to the market

This is the final straight of the entire race to broiler profits.

The last hurdle. Hit this one and all your efforts will be thrown away.

Get clued up on what matters during this critical time.

Pre-processing

Now we get to the point of fruit and we are ready to gather in the flock for slaughter.

Getting your broiler flock to the slaughterhouse is a combined effort.

The entire process is a collaboration between your farm and the transport company.

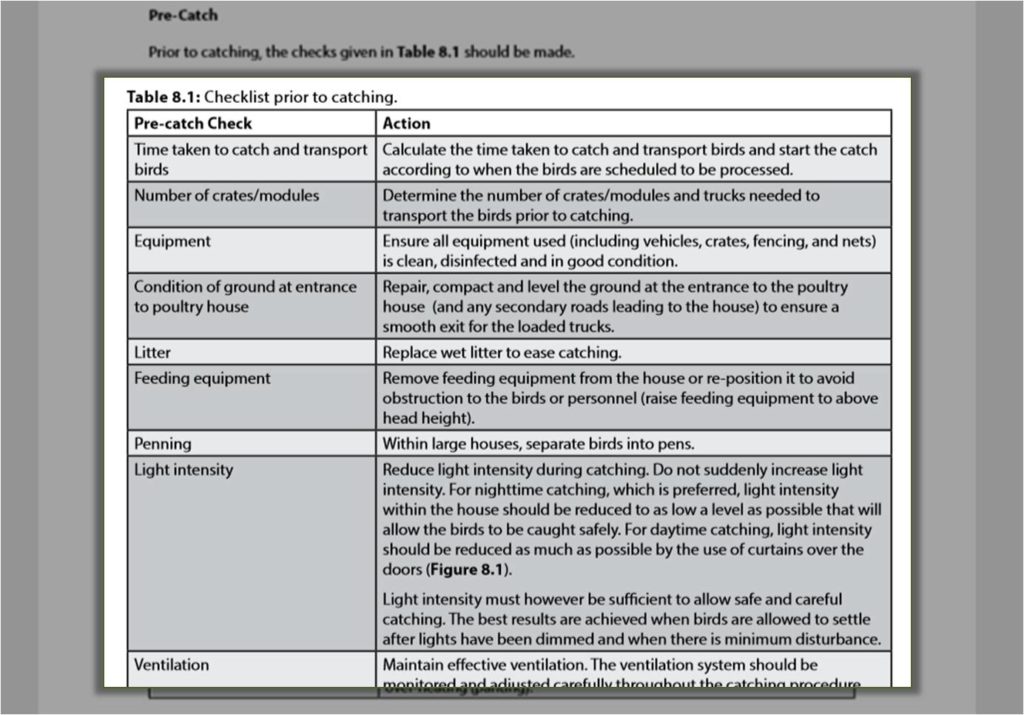

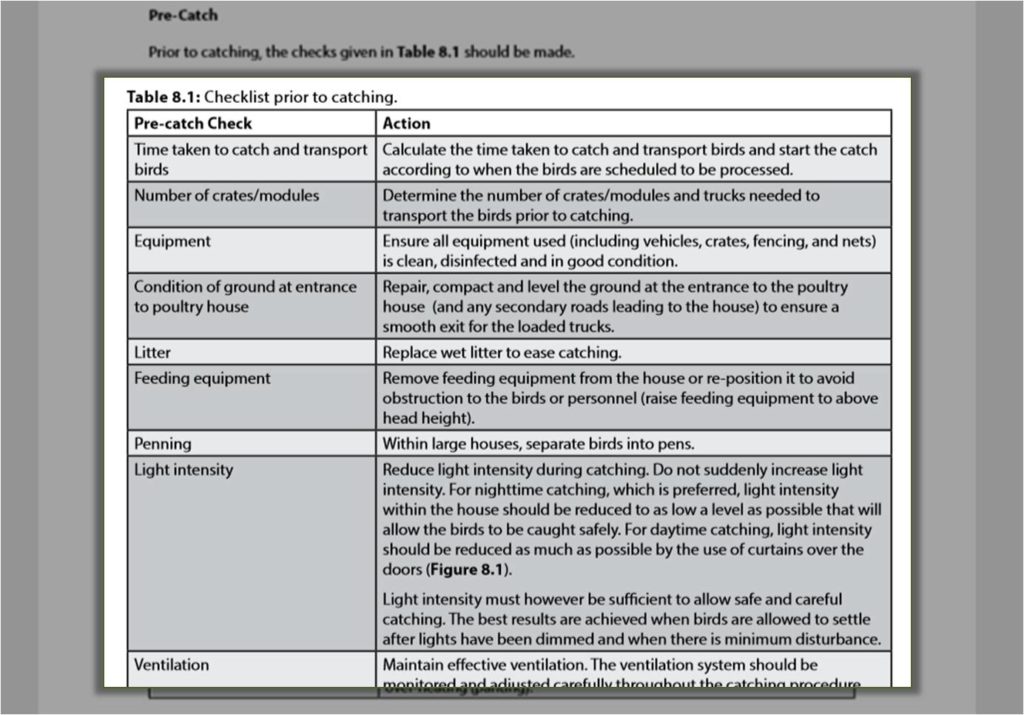

Here’s a checklist typical of what a broiler farm would have to do prior to transporting a mature flock:

As you can see, a lot of attention goes into the preparation of catching a flock on-site.

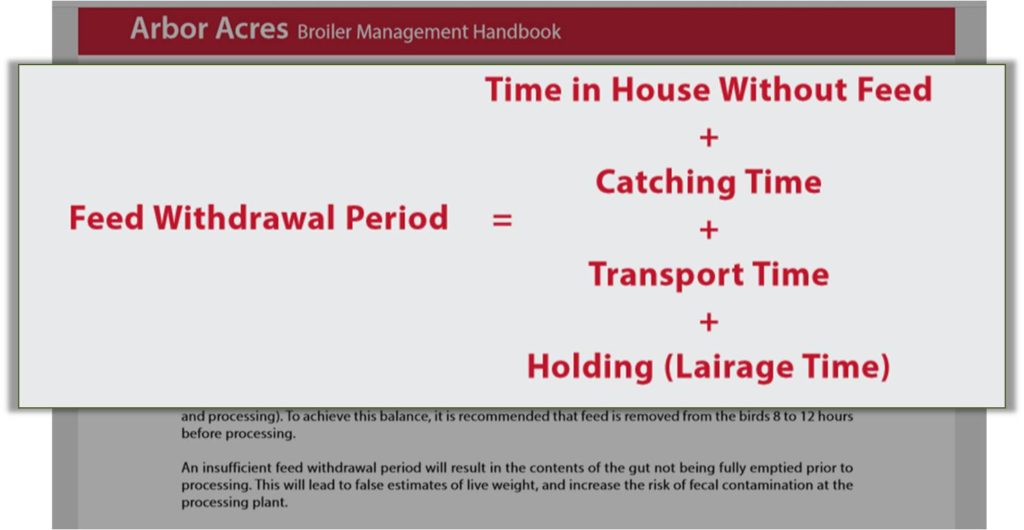

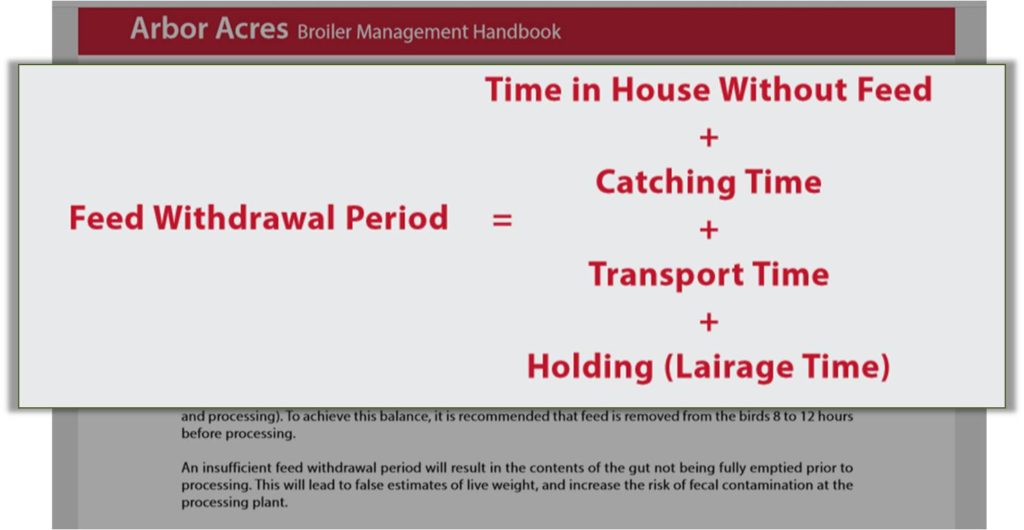

A point to consider when preparing a flock for processing is feed withdrawal in the run-up to the catch.

8-12 hours before transportation, flocks must be denied food.

This helps prevent faecal contamination during transport and throughout the slaughter process.

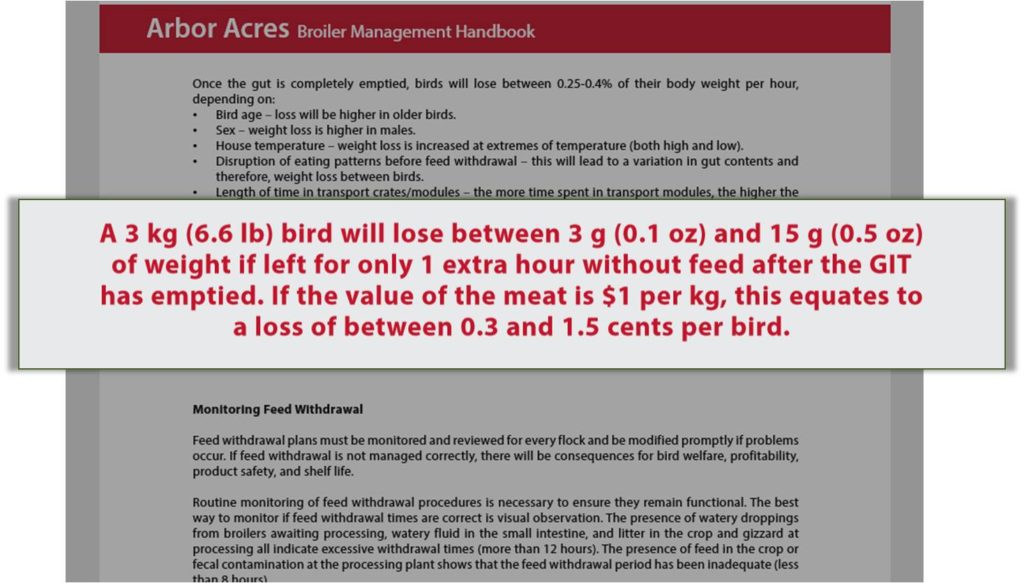

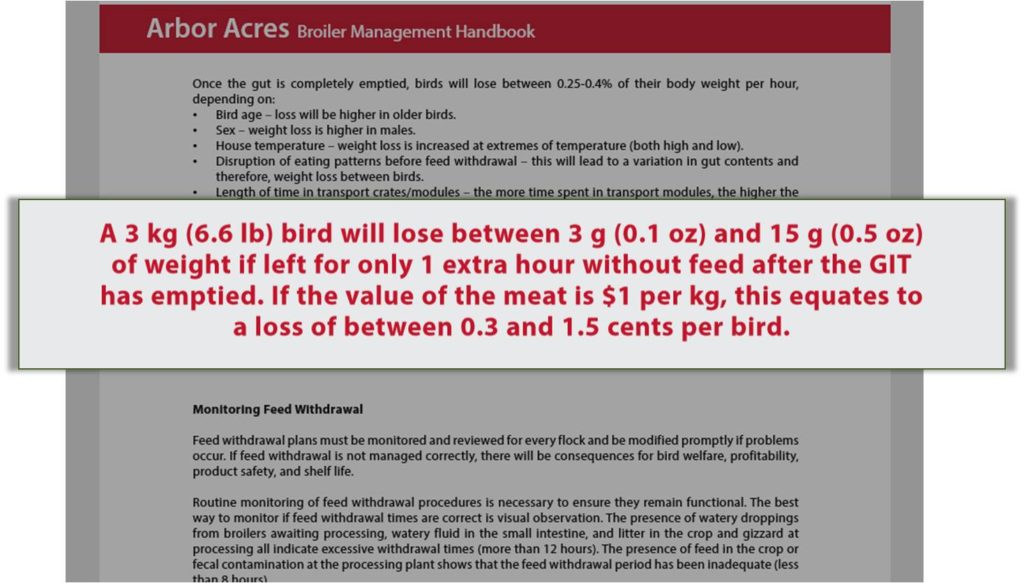

With all this time where your flock is ‘fasting’, the thought may have crossed your mind…

How will this affect my bird’s final market weight?

Here’s the answer:

On average, you can expect to lose 3g – 15g per bird before carcasses are prepared for market.

Factor this into your profit calculations.

It is unavoidable.

Marketing

Getting your broiler to market in order to make a profit takes strategy.

If ever you thought that all the hard work was over once your broilers were grown…

…think again.

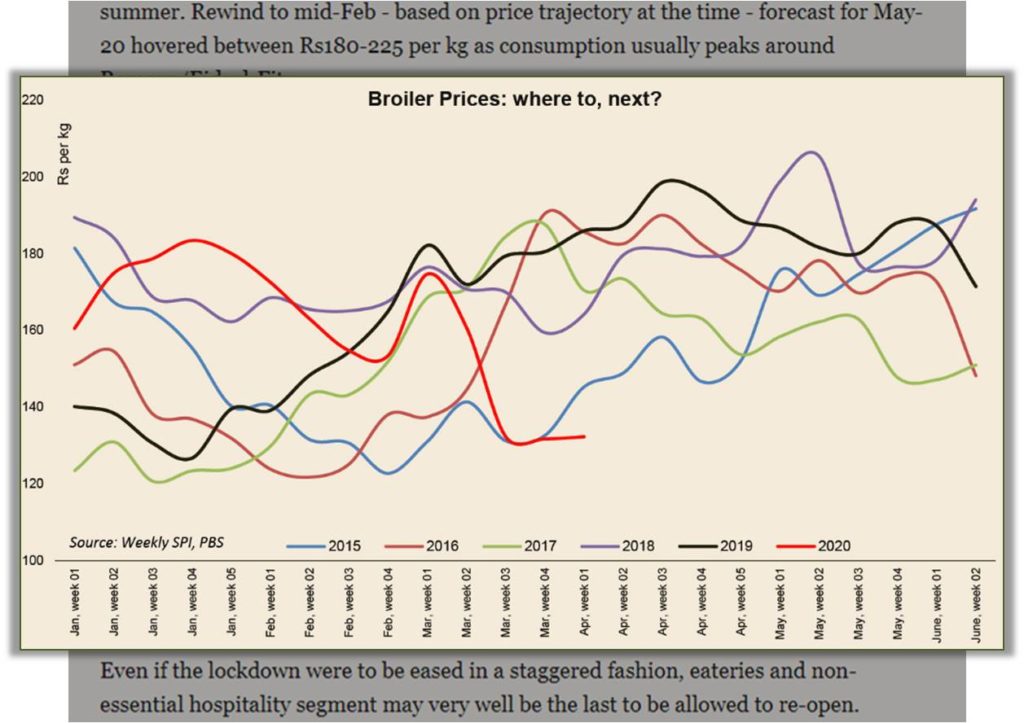

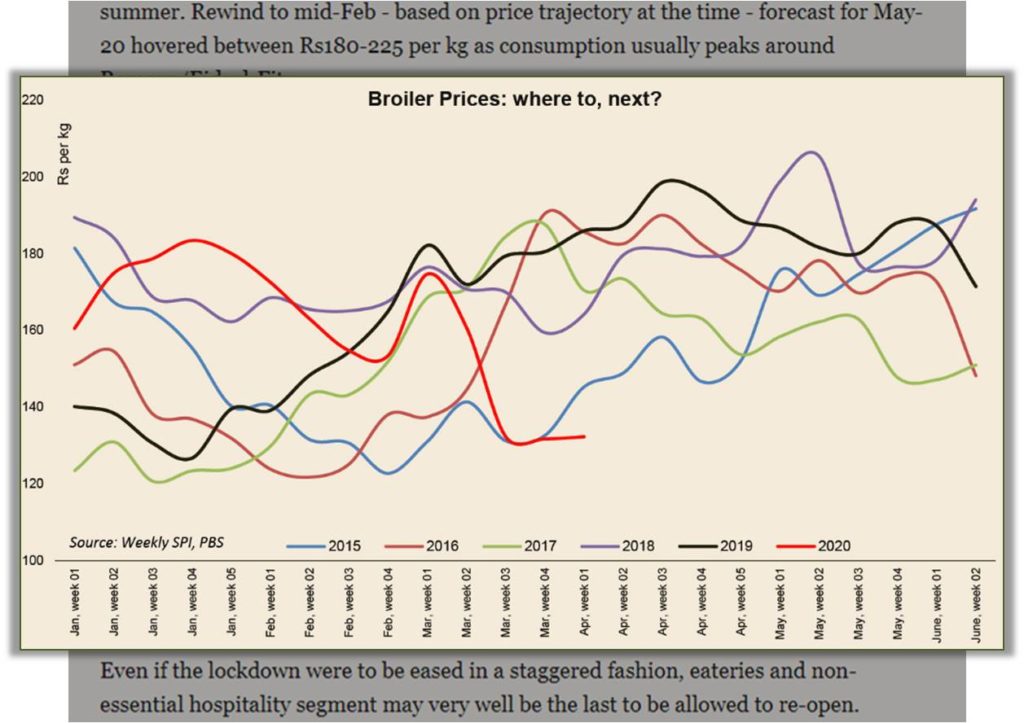

This graph of broiler price fluctuation should give you a feel for how difficult predicting the market can be:

(Were you able to make any sense of it?)

The takeaway?…

Markets move and pricing varies accordingly.

It’s difficult to call it.

No matter how in-tune with the latest news you are.

The variables within your control, however, are…

- farm type (intensive, organic)

- broiler weight,

- the volume of carcasses,

- meat yield

…these will have bearing on your revenue and the price you can fetch.

Keeping on top of your costs, in particular, the feed expenses will save you much profit potential.

Preserving the flock and not dropping points, or worse…

…losing key players…

…will keep your broiler farm on course for a successful and worthwhile finish.

Now, I’d like to hear from you…

I hope you picked up some good value from reading this broiler farming guide.

What are your thoughts?

Do you have experience of running a broiler farm already?

Or, are you still ‘thinking’ about is and need a little more guidance?

Either way, take the time now to leave a comment.

i have learned a lot

This was informative and very useful. Lots of insight gained. Thanks so much.

Glad to be of service, Emmanuel.

I plan to update this (and other pieces) from time to time.

I’ll email you when I do.

Let me know how you get on.

Speak soon.

Temi

Thank you so much. I gained a lot from your presentation. I am sure this will improve my practice and consequently my profit. I will get back to you.

the other thing i need now is to be assisted with the business plan for financial assistance

I want a business plan for financial assistance

This is very informative. It’s an eye opener.

Thanks

Exce;llent and thorough. However, needed is further elaboration on use of water and feed use ……, height adjustment of water and feeders as well. Thanks

Very interesting article, I’m about start investing in this business segment and was very helpfully, I highly recommend.

Cheers

good day i need your formular for poultry feed

I started with this new field just almost 2 months ago. Your article is very informative and interesting. It gave a feeling of security to be able to hopefully manage this successfully. Thank you!!!

Your article is very informing.

The other thing i need now is to be assisted with the business plan for financial assistance.

thanks

I am an aspiring broiler farmer and I’m currently making preparations to start. Your information on this site is priceless and I applaud your expertise and kindness.