The FAO projects that “…world demand for animal-derived protein will double by 2050.”

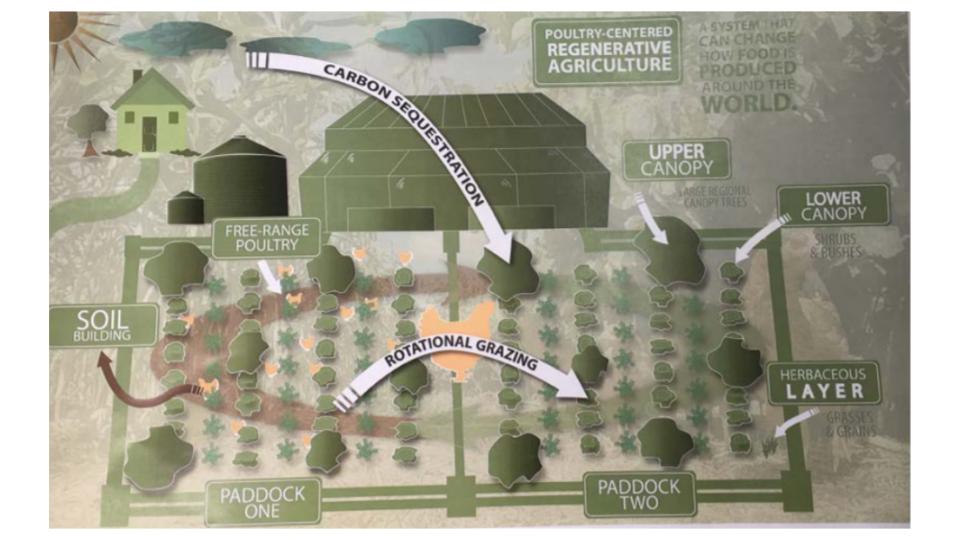

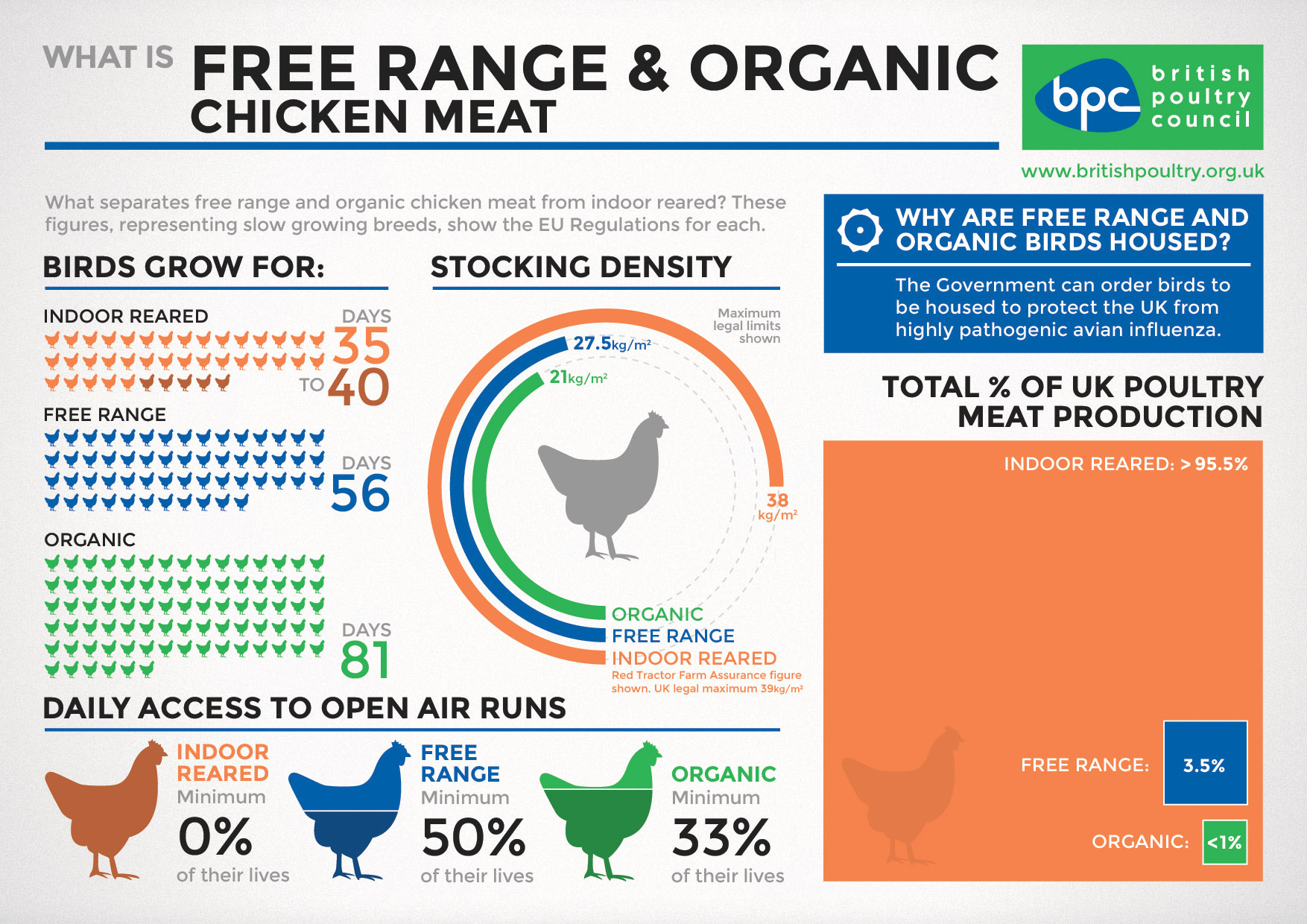

And compared with alternative land-based options like cattle rearing, chicken farming for meat and eggs has distinct start-up benefits.

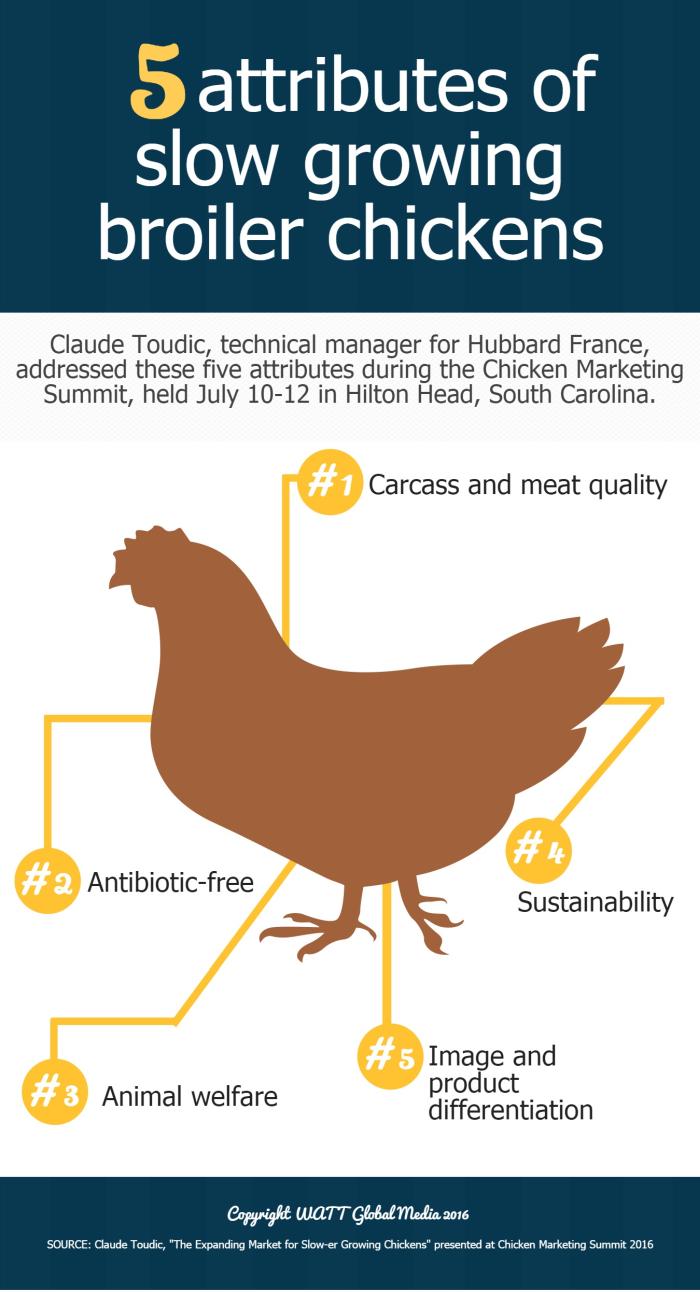

But what are the benefits of poultry farming?

And are there any drawbacks? [Read more…] about Benefits of Poultry Farming