Poultry Farm Capacity

This is an example poultry farming project report ‘capacity’ section…

What is this section of the report really telling the reader?…

And why is it important? (Get help with planning your production capacity.)

This example…

…relates to a layer poultry farm – making eggs the primary product.

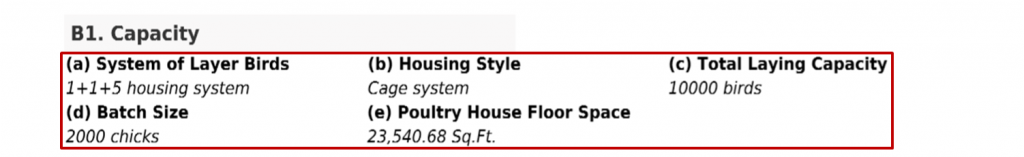

The adopted system within this example is a 1+1+5 layer housing system.

The housing system used for any poultry farming project defines the method by which your scope/capacity will be ‘turned over’ for production purposes.

In this type of layer housing set up, the farmer intends to build 5 layer houses, 1 brooder house and 1 grower house.

The denominator is the batch size. i.e. the numerical factor, which overall farm capacity is a multiplier of.

Let speak practically...

In the example above, the batch size planned for this poultry farm project is 2,000 chicks.

This means each time new chicks are bought from the hatchery, the farmer will buy 2,000 at a time.

Using the 1+1+5 housing set up (according to FAO guidelines), the farm at full poultry capacity will host:

2,000 brooders = 1x batch number (chicks aged from 1 day old-to-8 weeks old) in the brooder house2,000 growers = 1x batch number (birds aged between 9 weeks-to-20 weeks old) in the grower house10,000 layers = 5x batch number (birds aged between 21 weeks-to-72 weeks old) in 5 layer houses

Total farm size at any given interval in the rearing cycle, by number of birds, at full capacity will be 14,000 birds - with only 10,000 of those at most being birds of mature enough age to consistently lay eggs.

According to FAO recommendations for optimal poultry farming results, layer birds ought to be given 1,800cm2 minimum floor space within the poultry house.

This converts to: 1.93 sq.ft.

Floor space is critical to achieving optimal output levels in egg production. It impacts the bird's ability to reach target weight and size for producing the highest quality eggs, at the highest rate.

Insufficient space increases stress. More stress reduces weight of bird and egg productivity.

Recommendations also state that the poultry houses should be spaced apart by 30m distance.

Maintaining separate housing for each batch is a major factor for influencing bird health...

...avoiding disease or pathogen cross-contamination.

The overall floor space required for this particular poultry farming project is estimated as being just over 23,000 sq. ft.

Bird housing can either be deep litter floor space or caged system - the obvious detail, denoting the difference between the two...

(..to spell it out - with deep litter system houses, birds freely move within the poultry houses, caged systems keep birds in cages)

Caged systems require less floor space compared with deep litter housing.

But in this example, although the farm owner opted for cage houses, they maintained the total recommended floor space for a deep litter house to afford room for changing tact in the future...

And without need of redeveloping the housing should a change occur.

Further reading: